The FHWA is promoting the deployment of Digital As-Builts (DABs) in Round 6 of the Every Day Counts (EDC-6) Program. FHWA defines DABs as an accumulation of the data used during digital project delivery that provides a living record of built infrastructure for agencies’ future business needs. The latest FHWA Innovator, September/October, Issue 86, features a section on e-Ticketing and Digital As Builts that briefly defines the innovation and its benefits along with a short video of digital delivery efforts at Utah DOT.

During EDC-6, the NJ STIC has set forward goals for advancing Digital As-Builts, assessing the current stage of innovation as “development” and setting forward some near-term capacity-building actions.

This article reports on a brief Digital As-Builts Literature Scan and provides references to a select bibliography of research reports, strategic plans and other resource documents that may warrant closer inspection for innovation teams. The literature scan identifies some key definitions, benefits, emerging practices, recurring challenges and possible lessons when taking steps toward deployment of DABs.

Digital As-Builts Literature Scan

Introduction

A Digital As-Built (DAB) innovates by transferring what are typically 2D, paper records into digital, three-dimensional (3D) datafiles that can be regularly updated and shared with stakeholders throughout a project’s life cycle. This information becomes invaluable in the asset management and operations phase, in which it is crucial for agencies to have the most current, comprehensive data covering their facility’s construction. DABs can also be referred to as digital twins, intricate computerized copies of a road or bridge that simulate real-time conditions, allowing for predictive maintenance and more cost-effective mitigation projects.

Across the country, state departments of transportation (state DOTs) are beginning to adopt DABs requirements for future road and bridge projects. The Pennsylvania Department of Transportation (PennDOT), for instance, has established ambitious agency goals that by 2035, all agency projects will be bid upon using 3D models—which will be updated throughout the project’s development through completion, and then stored in a centralized database (PennDOT, 2020).

While industry standard software and practices are still emerging, the research, experiences, and challenges from DOTs nationwide can assist in the identification of promising practices and planning the transition to DABs.

Benefits of Digital As-Builts

Digital As-Builts are digitized, detailed records of completed construction projects. These could encapsulate roadways, bridges, barriers, berms, and any other facilities. What is revolutionary about DABs is their capacity to be used as digital twins, sophisticated mock-ups of the actual structure that enable agencies to streamline maintenance and improvement projects. DABs are simple to store and distribute, reducing the time and material costs from producing traditional 2D as-builts. Created using Computer Aided Drafting and Design (CADD) software, and updated with real-world readings, such as laser-based LiDAR, DABs are versatile and, increasingly, trustworthy records.

DABs were selected as part of the FHWA’s EDC-6, featured for their advances in safety, time savings, and quality (FHWA, 2021). In addition to providing high quality records that can optimize maintenance and asset management, DABs can streamline the project development process by easily showing decision makers the location of existing infrastructure. The safety benefits come, in part, from shorter work interruptions of regular traffic flows.

DABs offer the capability to reliably retain information throughout the project process, as data is handed over from one department agency to another. A UC-Davis report, conducted on behalf of the California Department of Transportation (Caltrans), suggests that DABs can reduce the risk of lost information considerably (Advanced Highway Maintenance and Construction Technology Research Center, 2020). Another report, prepared for the Kentucky Transportation Cabinet (KYTC) by University of Kentucky researchers, found that digital documentation could significantly build trust in as-built records. In 2018, KYTC spent $217,000 on new forensic investigations because handmade, paper as-builts were deemed untrustworthy (Kentucky Transportation Center, 2019). But DABs, especially when well-updated and held to high standards of detail, can reduce the need for new surveys and ultimately lower costs.

DABs feed into an integrated workflow in which completed facility information is readily accessible for asset management and maintenance. This process is an element of Civil Integrated Management (CIM), and involves the entire lifecycle of a facility.

Existing Practices

Though many aspects of life have been affected by increasing digitization, the as-built record-keeping process in state transportation remains rooted in the analog era. It was apparent, from the literature reviewed, that the majority of state transportation departments are still using 2D, paper as-builts for facility specifications.

When DABs were being used, they were as pilot projects to demonstrate their efficacy. Or, when a part of agency practice, as in the case of Caltrans, implementation was inconsistent and without sufficient coordination (AHMCTRC, 2020). Similarly, in Kentucky, some records were being stored digitally but without a designated central repository, or as hardcopies in a State Library and Archives warehouse for storage (KTC, 2019), offering little use for ongoing maintenance. States like Michigan and North Carolina, while looking to transition to digital records, were still working on their digital strategies and have yet to implement them as practice (FHWA, 2019).

Some states have recently established regulations requiring DABs, such as the Colorado Department of Transportation (CDOT), which updated the State Highway Utility Accommodation Code in 2021 calling for 3D subsurface models showing the location of utility lines in CDOT’s Right-of-Way (Colorado Department of Transportation, 2021). New York has established a 3D, 4D, and 5D requirement for certain megaprojects (such as the new Kosciuzko Bridge), that tie contractor payments to a continuously-updated model that is then revised with as-built information (FHWA, 2014). And Nevada, while requiring digital contract documents, has yet to add an as-built component. (Nevada Department of Transportation, 2021).

Many DOTs are being spurred to action by technological innovations and by prior EDC rounds (FHWA, 2015) and by the current FHWA’s EDC-6 e-Ticketing and Digital As-Builts initiative.

Emerging Practices

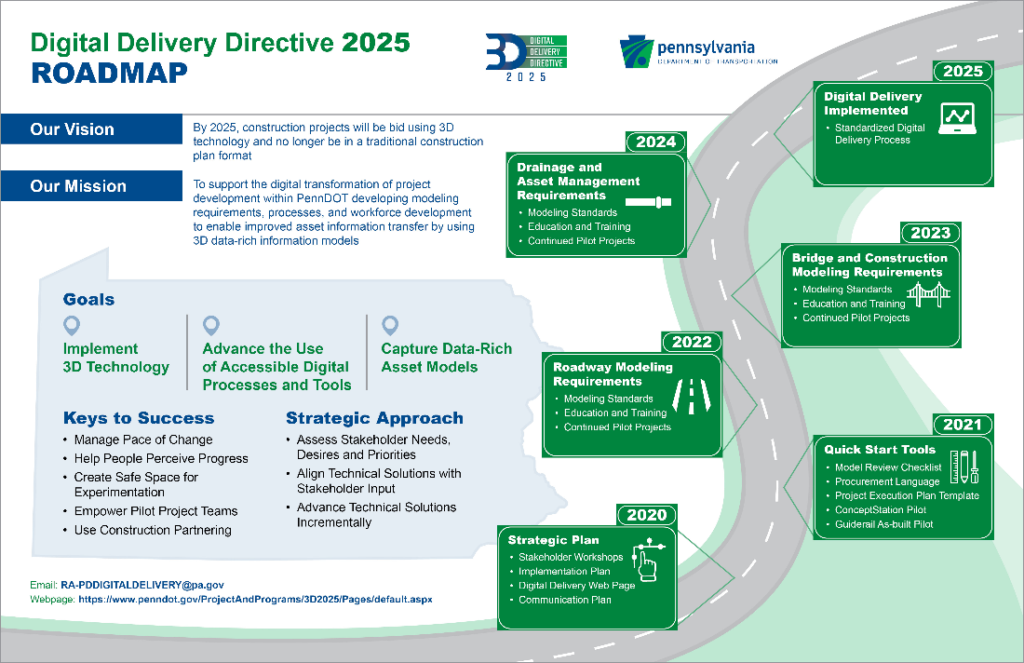

PennDOT appears at the leading edge in its development of a comprehensive DAB implementation plan, intending to adopt the digital delivery process as a department standard by 2025. For DABs, this involves a 5-year span spent developing standards and workflows for implementation. The planning process includes the functioning of various working groups for determining necessary infrastructure and modeling requirements, workspace needs, and training plans. Though PennDOT’s plan is still in progress, their Digital Delivery 2025 Strategic Plan offers a good example of a comprehensive, implementation document detailing steps the agency must take to make the transition to digital delivery (PennDOT, 2020).

Figure 1: Sample Digital Delivery Roadmap from PennDOT.

Agencies in other states are also piloting new standards. Many DOTs are planning to convert from paper records, and to capitalize on this transition by taking advantage of the new digital records in the asset management process.

The Utah Department of Transportation of Transportation (UDOT) has created a website describing the benefits of digital delivery, including the advantages of the use of Digital Twins (UDOT, 2021). UDOT’s site also contains sample deliverables packages for contractors, with technical specifications for roadways, drainage, and structures viewable in Bentley ProjectWise, and document management software used for DABs by several DOTs (e.g., Virginia, Washington, Kentucky, and others) (Virginia Department of Transportation, 2019).

Virginia is also working to establish new guidelines to support the Civil Integrated Management (CIM) process. The guidelines will set standards for Level of Detail (LOD) for 3D renderings, as some models can be inconsistent. Because they are intended to exist as exact records of the constructed facility, DABs are required to be the highest LOD (Level 400) (Virginia Department of Transportation, 2020).

Michigan and North Carolina are currently transitioning from 2D plan sheets to 3D models of contractual documents (FHWA, 2019). Both states plan to incorporate the records into asset and operations management over the project’s lifecycle.

NYSDOT, for a bridge reconstruction in the Catskill region, developed a 3D model for a contract document using Bentley iTwin Design Review software (CS Engineer Magazine, 2021). After the bridge is completed, the contractor is obligated to upload as-built information to the 3D model. This approach is being piloted in New York, but is not yet adopted practice.

In Minnesota, the state Department of Transportation (MnDOT), adopted special as-built requirements for certain regions in the state, starting in the Minneapolis-St. Paul Metropolitan area (FHWA, 2019). The agency also has a dedicated website with DAB specifications. For example, a barrier as-built report might include latitudinal and longitudinal X, Y, and Z coordinates, as well as a Plan ID referring back to the plan set.

Nearby, Iowa DOT has begun using geo-equipped devices from ESRI to capture vector and asset attribute data during the construction process (Iowa DOT Research, 2021). The geolocated data captures the location and geometry of facilities, and is then uploaded to a Microsoft SQL server. As opposed to developing a 3D model in the design process, and then updating it with as-built conditions, an after-the-fact approach captures three-dimensional as-built data outside of the Building Information Modeling (BIM) process.

Other states are exploring how they might apply these concepts to how they manage the planning, design, construction, and maintenance of their facilities. The literature resources reviewed made the benefits of DABs abundantly clear, and showed considerable progress being made, but they also identified challenges in the full-scale deployment of Digital As-Builts as standard practice.

Challenges

Several of the resources reviewed identified barriers for DOTs for implementing DABs. For Developing a Strategic Roadmap for Caltrans Implementation of Virtual Design Construction/Civil Integrated Management (2020), researchers surveyed Caltrans employees from various departments to learn more about the obstacles that the department faced. Similarly, University of Kentucky researchers surveyed Kentucky Transportation Cabinet (KYTC) staff, in Redefining Construction As-Built Plans to Meet Current Kentucky Transportation Cabinet Needs (2019). FHWA has also prepared reports on innovative digital records practices at various states that detail various challenges (FHWA, 2019).

These reports reveal some recurring themes on the challenges experienced by state DOTs that can be broken into two axes — Workflow and Workforce — as well as some solutions to surmount them.

Table 1: Examples of Workflow and Workforce Challenges and Solutions to DABs Implementation

| Axes | Challenges | Solutions | Examples |

| Workflow | Inconsistent Implementation | Develop robust, time-tested workflows | PennDOT |

| Workflow | Siloization | Facilitate interdepartmental coordination on projects and data updates | Caltrans |

| Workflow | Compatibility | Extensively test software workflows for technical errors, such as incompatibility | PennDOT |

| Workflow | Standards | Create file, format, and procedural standards (i.e. designated Levels of Detail). Require compatible software infrastructure to support DABs | PennDOT, UDOT, VDOT, NDOT, CDOT |

| Workforce | Digital Competencies | Educate employees with ongoing trainings that ease into DAB process | PennDOT |

| Workforce | Compliance | Educate for and enforce DAB protocols | UDOT, MnDOT |

For example, the Caltrans report made clear that the development of an agency-wide workflow was paramount. Without one, various divisions were inconsistent and ineffective at capturing, maintaining, and communicating about DABs. Caltrans Roadway Design and Structures Design divisions fell short in updating and sharing the existence of updates with one another (AHMCTRC, 2020).

Regarding particular software, files, and workstations, care must be taken in the workflow design process to ensure compatibility. In Caltrans case, the Roadway Design and Structures Design divisions were using incompatible 3D modeling software. Iowa DOT experienced a similar issue, in which 3D, geolocated models created using ESRI software were then unable to be meaningfully edited in Bentley MicroStation (Iowa DOT Research, 2021). In addition, Iowa DOT’s 3D models, designed as part of a BIM process for a bridge girder replacement project, could not be edited because of the file type. An audit of Kentucky’s Transportation Cabinet found that, though there was a central repository for digital records (Bentley’s ProjectWise), files were uploaded inconsistently (KTC, 2019). While NYSDOT had planned, during the construction of the new Kosciusko Bridge, to continuously update a 3D model to show newly built components, they experienced severe network capacity constraints that prevented them from doing so (FHWA, 2014). Upfront planning, interdepartmental collaboration and testing ensures that DABs potential is unleashed.

The second tier of challenges arise from issues with workforce adoption. An FHWA case study looking at digital record keeping at MnDOT highlights difficulty with securing buy-in from construction staff to comply with new DAB requirements (FHWA, 2019). The KYTC study singled out a lack of digital competencies from older employees as one barrier towards adopting these new technologies. Change is difficult to implement, but especially when staff have become accustomed to the same practice for decades.

Recommendations

For Workflow design, a considered and deliberative process is required. Agencies must convene working groups of stakeholders and learn about department-specific concerns and established processes. Several years may be required to design new DAB workflows that maximize the potential of the new technology, and ensure that the infrastructure is in place to support and encourage staff to follow these workflows.

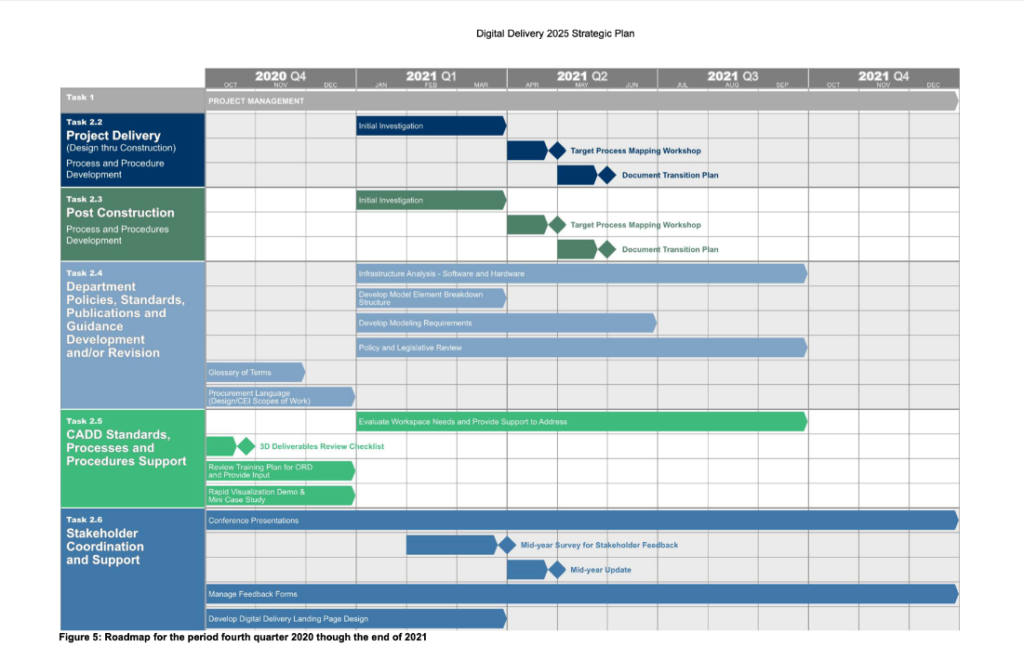

PennDOT’s plan for implementing digital delivery is an instructive and thorough model document on the subject (PennDOT, 2020). The agency’s Digital Delivery Strategic Plan breaks tasks down into actionable steps, such as Task 2.3, Post Construction Process and Procedures Development, scheduled from Q2-Q3 of 2021, which will map out new requirements and a plan to realize the new processes. An agency wishing to avoid siloization would do well to consult the UC-Davis study that provides itemized, exact solutions.

Figure 2: Another visual representation of PennDOT’s Digital Delivery Roadmap.

Architects of the new DAB workflow should be careful to promote interdepartmental collaboration, as well as select compatible software that supports such a goal. Bentley Systems design, engineering, and review software—MicroStation, OpenRoads, and ProjectWise, principally—appear to be the most consistently used across the country (AHMCTRC, 2020). For determining a cohesive workflow, it is imperative that varying software have compatibility with one another—and that they are consistently used across the department.

For the issue of designated detail levels, both Minnesota and Virginia have developed tables with standards specifying when and where to make DABs as accurate as possible, such as whether to survey the constructed facility at a detail of one foot or one meter (FHWA, 2019). The overall objective of the department may help to guide the development process: how does the agency aim to utilize BIM technology? A representative DAB could help to dramatically increase the efficiency of future maintenance or upgrade projects, but only if the appropriate standards are first put in place.

The Workforce presents complementary challenges and solutions. A technology is only useful if it is appropriately deployed—part of the workflow design process should include consultation with staff on specific barriers they face in their daily adoption of the technology. What might be preventing them from doing so? What types of trainings are required to achieve core competencies? Interviewing staff stakeholders will also help to determine accountability measures that could be put in place, for both staff and contractors, to help ensure consistent compliance with new workflows (KTC, 2019).

Moving Forward

Digital As-Builts are a promising technological innovation that can reduce inefficiencies in the life cycle of a transportation facility. If appropriately deployed, DABs can maximize the value of a project, eliminating the need for new forensic investigations, and retaining information as it is handed off from one phase to the next. Many of the DOTs surveyed are considering and incorporating innovative practices into their DAB implementation. Both Caltrans and KYTC, for example, are studying the use of laser-based scanning technologies to develop geolocated 3D models post-construction. In the coming years, as DABs are adopted into practice, more case studies will become available for reference.

From the resources reviewed, it was apparent that Digital As-Builts are promising technology that can streamline record-keeping and save transportation agencies both time and money.

Bibliography

Advanced Highway Maintenance and Construction Technology Research Center (2020). Developing a Strategic Roadmap for Caltrans Implementation of Virtual Design Construction/Civil Integrated Management. California Department of Transportation.https://dot.ca.gov/-/media/dot-media/programs/research-innovation-system-information/documents/final-reports/ca20-3178-finalreport-a11y.pdf

Colorado Department of Transportation. (2021). State Highway Utility Accommodation Code. Colorado Department of Transportation. https://www.sos.state.co.us/CCR/GenerateRulePdf.do?ruleVersionId=9244&fileName=2%20CCR%20601-18

CS Engineer Magazine. (2021). NYS DOT Delivers First Model-based Contracting 3D Project in Its History; Delivered the Project Under Budget and Restored a Critical Bridge to the Community. CS Engineer Magazine. https://csengineermag.com/nys-dot-delivers-first-model-based-contracting-3d-project-in-its-history-delivered-the-project-under-budget-and-restored-a-critical-bridge-to-the-community/

Federal Highway Administration. (2014). 4D and 5D Modeling: NYSDOT’s Approach to Optimizing Resources. Federal Highway Administration. https://www.fhwa.dot.gov/construction/3d/hif16024.pdf

Federal Highway Administration. (2015). 3D Engineered Models: Schedule, Cost and Post-Construction: Fact Sheet. https://www.fhwa.dot.gov/innovation/pdfs/factsheets/edc/edc-3_factsheet_3d_engineered_models.pdf

Federal Highway Administration (2021). e-Ticketing and Digital As-Builts. Federal Highway Administration. https://www.fhwa.dot.gov/innovation/everydaycounts/edc_6/eticketing.cfm

Federal Highway Administration. (2019). Michigan DOT Digital Delivery Working Group. Federal Highway Administration. https://www.fhwa.dot.gov/construction/econstruction/edc4/hif19033.pdf

Federal Highway Administration. (2019). Minnesota and Iowa DOT Solutions for Capturing Asset Information During Construction. Federal Highway Administration.https://www.fhwa.dot.gov/construction/econstruction/hif19075.pdf

Iowa DOT Research. (2021). Development of Digital As-Built for Use in Future Asset Management Applications. Iowa Department of Transportation.https://ideas.iowadot.gov/subdomain/stic-incentive-funds/end/node/3410?qmzn=iKFrYf

Kentucky Transportation Center. (2019). Redefining Construction As-Built Plans to Meet Current Kentucky Transportation Cabinet Needs. Kentucky Transportation Cabinet. https://uknowledge.uky.edu/ktc_researchreports/1630/

National Cooperative Highway Research Program. (2015). Advances in Civil Integrated Management. Scan Team Report. NCHRP Project 20-68A, Scan 13- 02. http://onlinepubs.trb.org/onlinepubs/nchrp/docs/NCHRP20-68A_13-02.pdf

Nevada Department of Transportation. (2021). CAD Standards and Information. Nevada Department of Transportation. https://www.dot.nv.gov/doing-business/about-ndot/ndot-divisions/engineering/design/cadd-standards-and-information

North Carolina Department of Transportation. (2020). Perspectives on Anticipated OpenRoads Designer (ORD) Technological Benefits. North Carolina Department of Transportation. https://connect.ncdot.gov/resources/CADD/OpenRoads%20Designer%20Documents/NCDOT%20Research%20and%20Innovation%20Summit_ORD%20Presentation_10-14-20_Final.pdf

Pennsylvania Department of Transportation. (2020). Digital Delivery Directive 2025 Final Strategic Plan. Pennsylvania Department of Transportation. https://www.penndot.gov/ProjectAndPrograms/3D2025/Documents/Final%20Strategic%20Plan%20V1.0.pdf

Utah Department of Transportation. (2021). Digital Delivery. Utah Department of Transportation. https://digitaldelivery.udot.utah.gov/pages/bdc1336e1ade43d5bac2deca0e3e4837

Virginia Department of Transportation. (2020). 3D Model Development Manual. Virginia Department of Transportation. http://www.virginiadot.org/business/resources/LocDes/3D_Model_Development_Manual.pdf

Virginia Department of Transportation. (2019). Instructional and Informational Memorandum. Virginia Department of Transportation. http://www.virginiadot.org/business/resources/LocDes/IIM/IIM118.pdf Washington State Department of Transportation. (2017). Electronic Engineering Data Standards. Washington State Department of Transportation. https://wsdot.wa.gov/publications/manuals/fulltext/M3028/ElectronicEngDataStandards.pdf