May 13, 2024 | Innovation Interview, Innovation Spotlight, News, Research Project, Research Showcase, Research Spotlight

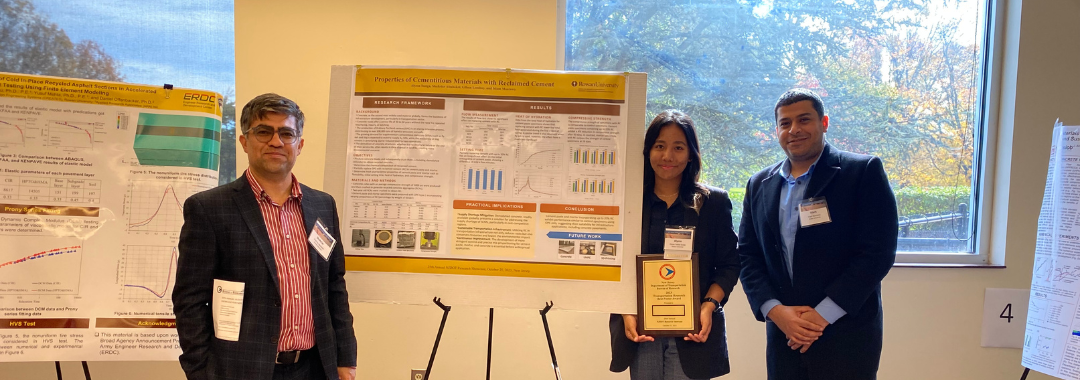

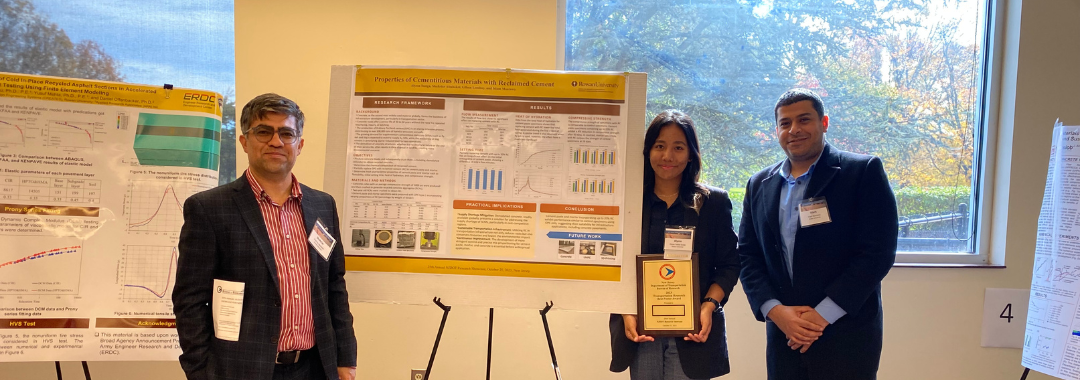

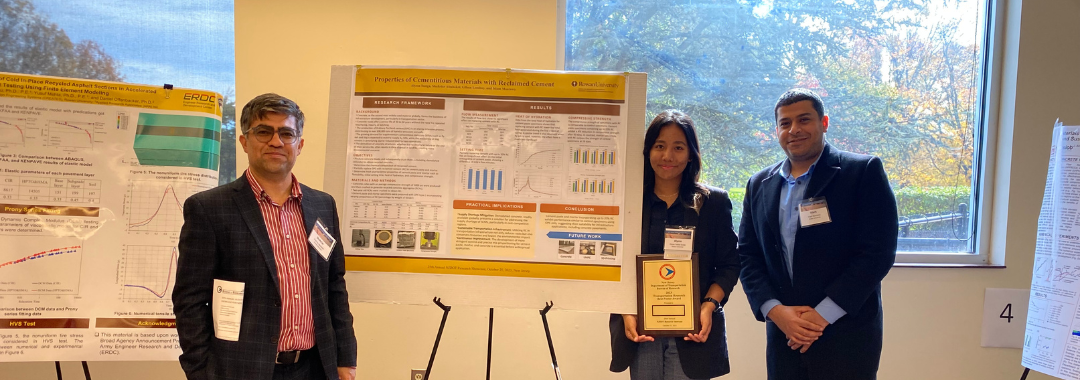

Concrete production is energy intensive, and requires materials that are both challenging, and expensive to acquire. Material engineers are seeking alternative materials that are more cost-effective and carbon-friendly, but also operate successfully as road and...

Apr 2, 2024 | Innovation Interview, Innovation Spotlight, News, Research Project, Research Spotlight

Biometric sensors have long been used in cognitive psychology to measure the stress-level of individuals. These sensors can measure a variety of human behaviors that translate as stress: the movement of eyes, stress-induced sweat, and heart rate variability. Recently,...

Mar 4, 2024 | Innovation Spotlight, News

New Jersey Department of Transportation, alongside other state and regional agencies, has embarked on ambitious initiatives to revolutionize its transportation fueling infrastructure through the National Electric Vehicle Infrastructure (NEVI) Deployment and through...

Feb 13, 2024 | Innovation Interview, Innovation Spotlight, Innovative Initiative, News, Research Spotlight

UHPC for Bridge Preservation and Repair is a model innovation that was featured in FHWA’s Every Day Counts Program (EDC-6). UHPC is recognized as an innovative new material that can be used to extend the life of bridges. Its enhanced strength reduces the need for...

Feb 7, 2024 | Innovation Interview, Innovation Spotlight, Innovative Initiative, News

Enhancing Performance with Internally Cured Concrete (EPIC2) is a model innovation in the latest round of the FHWA’s Every Day Counts Program (EDC-7). EPIC2 is recognized as an innovative new technique that can be used to extend the life of concrete bridges and roads....

Sep 7, 2023 | Innovation Spotlight, Innovative Initiative, News, NJ STIC, Online Learning

The New Jersey Department of Transportation’s Traffic Incident Management (NJTIM) training is now available as an online, self-guided course. Bringing first responder training program to an online training platform should make it easier for even more emergency and...