The 25th Annual NJDOT Research Showcase provided an opportunity for the New Jersey transportation community to learn about the broad scope of academic research initiatives underway and share technology transfer activities being conducted by institutions of higher education partners and their associates. The annual event serves as a showcase to highlight the benefits of transportation research, including NJDOT’s own program. This event was an in-person event with a livestreaming option with sessions held from 9:00am-2:45pm on October 25, 2023.

This year’s Showcase theme, “Commitment to Safety,” served as the organizing framework for the speakers and panelists during the morning plenary session. Throughout the day the Research Showcase featured presentations on infrastructure, safety, mobility, and equity topics being performed by research faculty, staff, students, and NJ agencies. Several awards were presented in recognition of research and implemented innovations.

The Research Showcase Program Agenda provides more information on the day’s proceedings, including presented topics and invited speakers. Recordings of the plenary and breakout sessions, and the presentations and posters shared during the event can be found below.

MORNING

WELCOMING AND INTRODUCTORY REMARKS

David Maruca, Program Development Administrator, Rutgers Center for Advanced Infrastructure and Transportation, served as the moderator for the morning session, offering some housekeeping remarks and walked through the morning’s agenda.

Andrew Swords, Director, New Jersey Department of Transportation Division of Statewide Planning, welcomed attendees to the 25th Annual NJDOT Research Showcase, explaining the purpose and theme of the event, “Commitment to Safety,” and acknowledging several parties, including NJDOT Bureau of Research staff, Rutgers-CAIT, and the leadership of NJDOT and FHWA for their planning and participation in the day’s event along with the research partners whose work was being showcased.

Diane Gutierrez-Scaccetti, Commissioner, New Jersey Department of Transportation, thanked several partners for their involvement in the event and reflected on the history of the Research Showcase Event on the occasion of the 25th Anniversary. In framing the day’s activities, Commissioner Gutierrez-Scaccetti recognized the event’s “Commitment to Safety” theme and the foundational importance of transportation for affecting positive change, improving the quality of life, and the shape of New Jersey’s transportation system. In her remarks, she appealed to attendees to advance community-centered transportation and to commit to considering the needs of ALICE (Asset Limited, Income Constrained, Employed) persons when devising research questions and in carrying out their day-to-day activities with the goal of planning, building and maintaining a more safe, equitable and sustainable transportation system.

Robert Clark, Division Administrator, Federal Highway Administration New Jersey Division acknowledged the importance of the NJDOT Research Showcase’s “Commitment to Safety” theme. He described several policy and research commitments at U.S. DOT, FHWA Turner-Fairbanks Research Center and the Volpe Center that are intended to “double-down” on improving safety, reducing fatalities and strengthening the culture of safety in transportation. In closing out, Mr. Clark shared the USDOT Commissioner’s message that roadway deaths is a crisis that is urgent, unacceptable and preventable; those in attendance should see that their work and research into safety can prove that roadway fatalities need not be inevitable.

KEYNOTE ADDRESS

Dr. Allison E. Curry, PhD, MPH, Associate Professor of Pediatrics, Children’s Hospital of Philadelphia delivered the keynote address on the New Jersey Safety and Health Outcomes (NJ-SHO) Data Warehouse. In organizing her talk, she explained the vision behind the development of the data warehouse over the last 15 years, the data sources that have been employed, its innovative features that can support meaningful research, and her vision for future research and collaborations drawing upon the data warehouse platform.

Dr. Curry described how crash data can be linked to other data sets to extend the period of study about crashes. She explained the data warehouse has been built through an array of administrative data partnerships with NJ agencies (e.g, public health, hospital, motor vehicle, police, medicare and medicaid, etc.) that have been linked alongside rich community-level indicators available at the census tract level to create a robust data tool for traffic safety research.

Her talk highlighted some of the limitations of crash reports that explain the need for data integration with other administrative record sources. She emphasized the longitudinal features of the data warehouse and explained how its linkages to health and motor vehicle records makes it possible to study specific populations segments — for example, teens on the autism spectrum. In her example, she described her research demonstrating how the data sets could be used to investigate the percentage of teens with autism who acquired driver licenses to increase their travel independence. She also could compare whether crash rates were comparable between this group and other teens in their age cohort at 12 months and 48 months from receipt of a license.

Dr. Curry also highlighted data limitations on reporting of race and ethnicity on NJ crash and licensing data and how other data sources (e.g., hospital discharge, electronic health records, birth and death data, etc. ) can be used to look at race and ethnic differences in non-fatal crash outcomes. In doing so, she highlighted how a probability-based algorithm, Bayesian Surname Geocoding (Sartin 2021), developed by the RAND Corporation, has been applied to estimate the race and ethnicity of driver licenses and address a source of race and ethnic bias in hospital record reporting due to varying levels of hospital usage.

Dr. Curry touched upon several of NJ SHO’s innovative features that can enable research. Among other points, she contrasted the “urban planning lens” which considers the place in which an accident occurred with the “public health lens” which seeks information about persons who are crash victims and where they live.

She also offered illustrative examples of how the NJ-SHO can be linked to vehicles to examine types of crashes, vehicle types and the injuries incurred which can reveal differences among more vulnerable populations (e.g, youth, elderly, poor) from other populations.

Dr. Curry closed her talk with a sneak preview of a new interactive data dashboard, NJ-SHO Center for Integrated Data, currently in development in association with the NJ Division of Traffic and Highway Safety. She noted how the dashboard tool will help practitioners efficiently use available data sets in ways that will mirror the metrics of the NJ Strategic Highway Safety Plan with a focus on persons as well as community resilience and social vulnerability equity-oriented measures.

Dr. Curry responded to questions in a Q&A session that followed her keynote remarks.

MORNING SESSION PANEL DISCUSSION

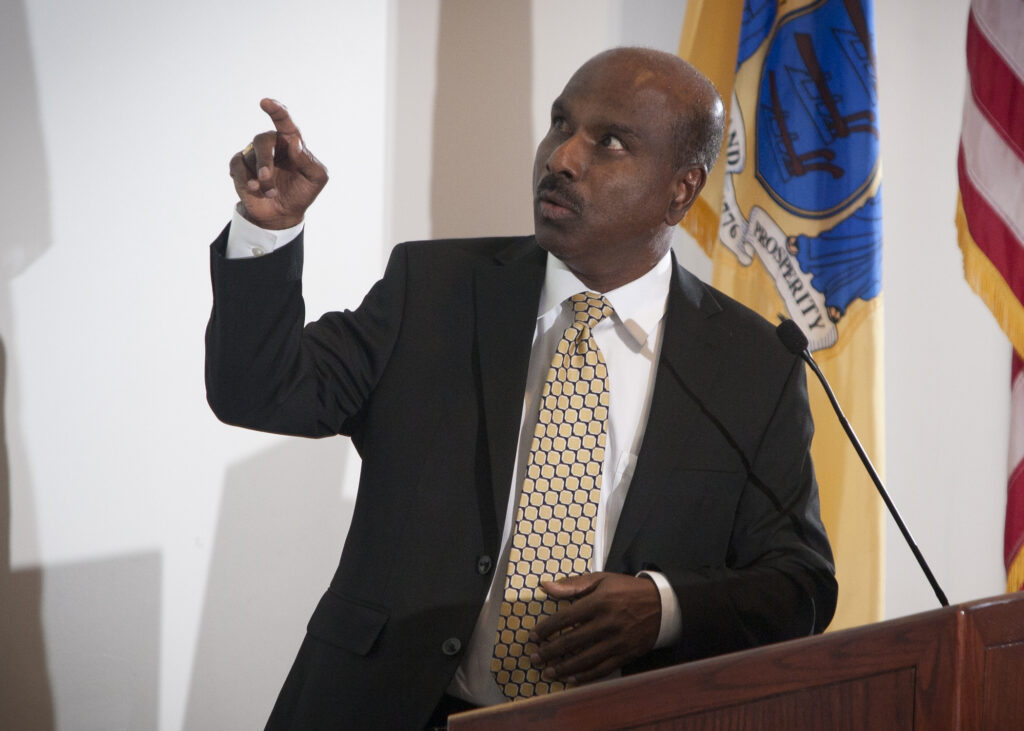

An interactive panel discussion, “How is New Jersey Department of Transportation Addressing Safety?” followed the keynote session with state NJDOT staff representatives who presented examples of the safety initiatives underway at NJDOT and reflected on persistent challenges and opportunities for addressing transportation safety in New Jersey.

The panelists included:

- Andrew Swords, Director, New Jersey Department of Transportation Division of Statewide Planning.

- Syed Kazmi, Section Chief, New Jersey Department of Transportation Division of Traffic Engineering

- Kurt McCoy, Supervising Engineer, New Jersey Department of Transportation Division of Operations Support

- Sangaran Vijayakumar, Project Management Specialist 3, New Jersey Department of Transportation Division of Project Management

- Hirenkumar Patel, Principal Engineer, New Jersey Department of Transportation Division of Transportation Mobility

Participants responded to a series of questions posed by the moderator and by the audience members.

Panelists shared their views on how the New Jersey Department of Transportation addresses safety. Photo by Steve Goodman.

AWARDS

The program continued as Dr. Giri Venkiteela Research Scientist, Bureau of Research, New Jersey Department of Transportation announced several awards given in recognition of research, innovation and implementation efforts. Below is a listing of the award winners presented at this year’s showcase:

- 2023 Outstanding University Student in Transportation Research Award – Alissa Persad, Rutgers University, Ms. Persad was being recognized in part for her valued contributions to the Innovative Materials for Quick Patching and Repair of Concrete project.

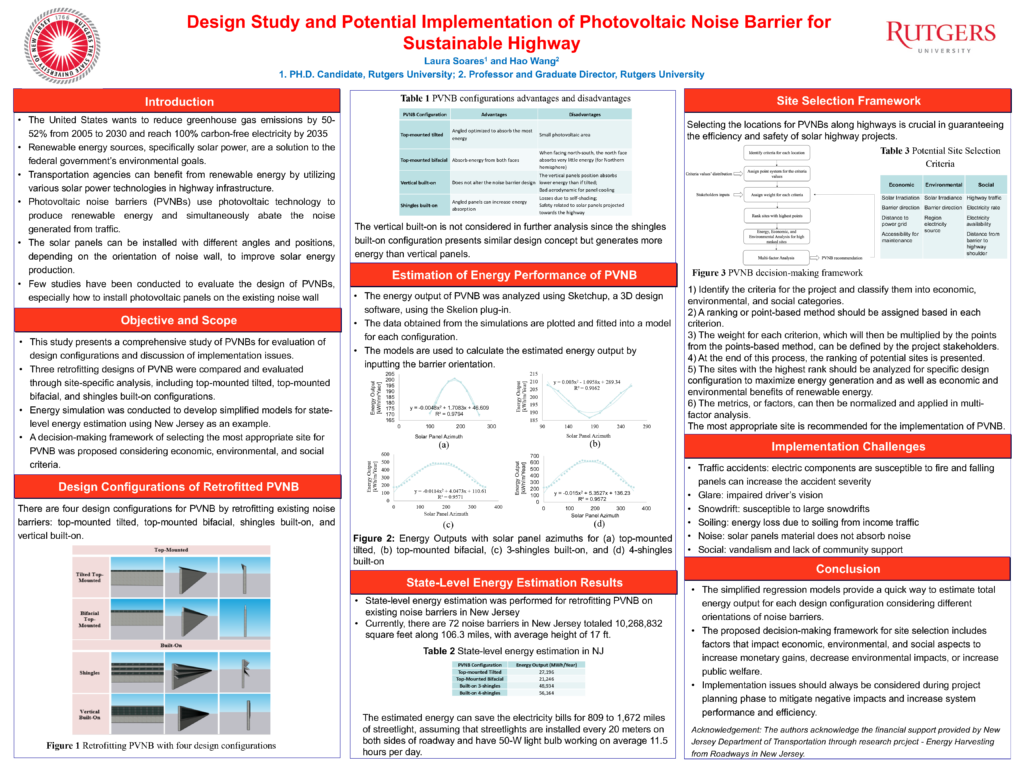

- 2023 NJDOT Research Implementation Award – Dr. Hao Wang, Rutgers University Energy Harvesting on New Jersey Roadways. This project identified potential energy harvesting technology for applications on roadways and bridges and conducted feasibility analysis and performance evaluation of the selected technologies for large-scale and micro-scale energy generation.

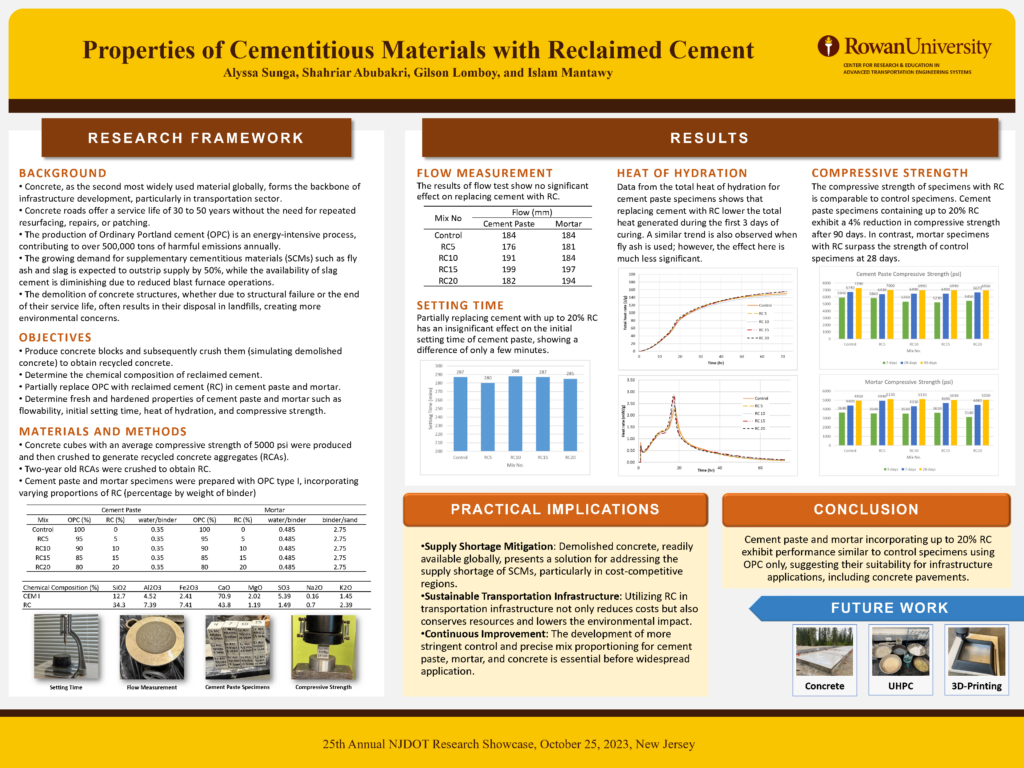

- 2023 Best Poster Award – Alyssa Yvette Sunga, Rowan University, Properties of Cementitious Materials with Reclaimed Cement. This poster described research activities that obtained recycled concrete; determined the chemical composition of reclaimed cement; partially replaced ordinary Portland cement with reclaimed cement in cement paste and mortar; and determined the fresh and hardened properties of cement paste and mortar through tests measuring flowability, initial setting time, heat of hydration, and compressive strength.

- 2023 Research Champion Excellence Award – Thomas Bushar, New Jersey Department of Transportation, Materials. This award recognizes Mr. Busher’s dedication while serving as a Technical Advisory Panel member for The Evaluation of Different Paint Systems for Over-Coating Existing Structural Steel project. The award notes that his commitment greatly contributed to the success and implementation of this research project.

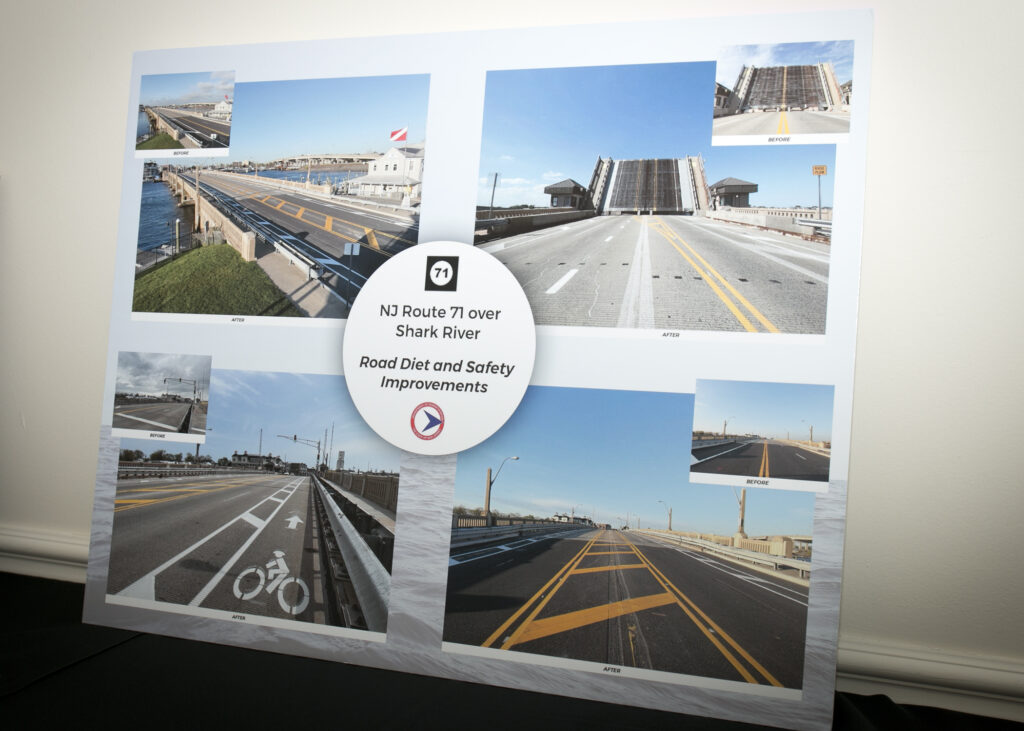

- 2023 NJDOT Build a Better Mousetrap Award – Gerald Oliveto, P.E. New Jersey Department of Transportation, Moveable Bridge Unit. The “Route 71 Over Shark River Road Diet” is a road diet project that preserves an old historic drawbridge while improving safety and saving money. When the Route 71 Drawbridge over Shark River between Belmar and Avon-by-the-Sea in Monmouth County suffered a mechanical failure in September 2021, engineers worked quickly to design and implement a solution that would both preserve the drawbridge and keep it in safe operation. The traffic load needed to be redistributed and balanced properly across the span to keep the bridge opened. NJDOT implemented a road diet across the bridge, which allowed the Department to address several safety issues. Traffic over the bridge was reduced from one northbound lane and two southbound lanes to one lane in each direction. Signal timings were adjusted, safety improvements at surrounding intersections were installed, and highway signage was enhanced. In addition, bike lanes that had previously ended abruptly were carried across the drawbridge utilizing an innovative bicycle-safe grid, a first-of-its-kind achievement in New Jersey. Through this $150,000 project completed in May 2022, the Route 71 over Shark River Road Diet project improved traffic flow, increased safety, and reduced congestion in a busy tourist area.

PRESENTATION OF AWARDS

Steve Goodman.

AFTERNOON

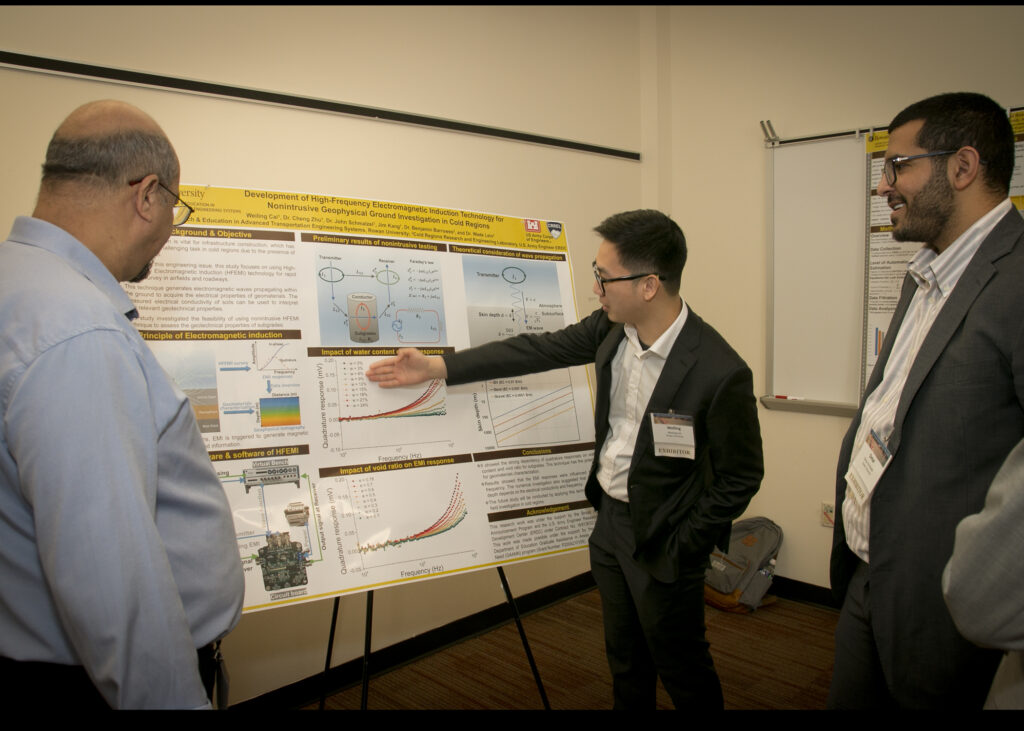

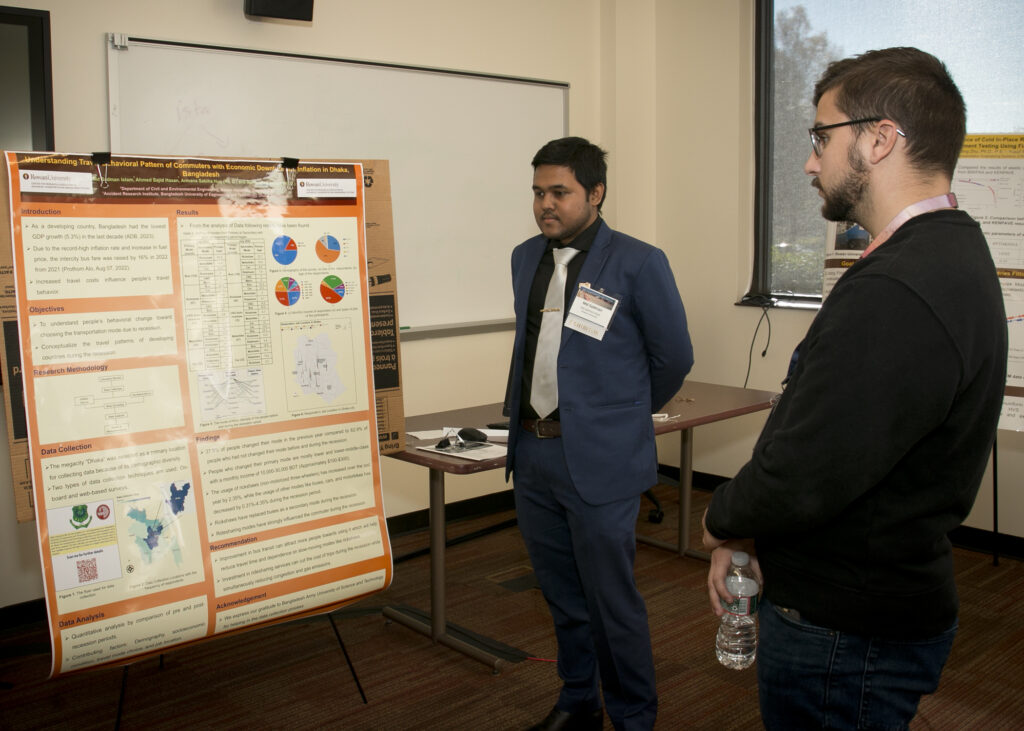

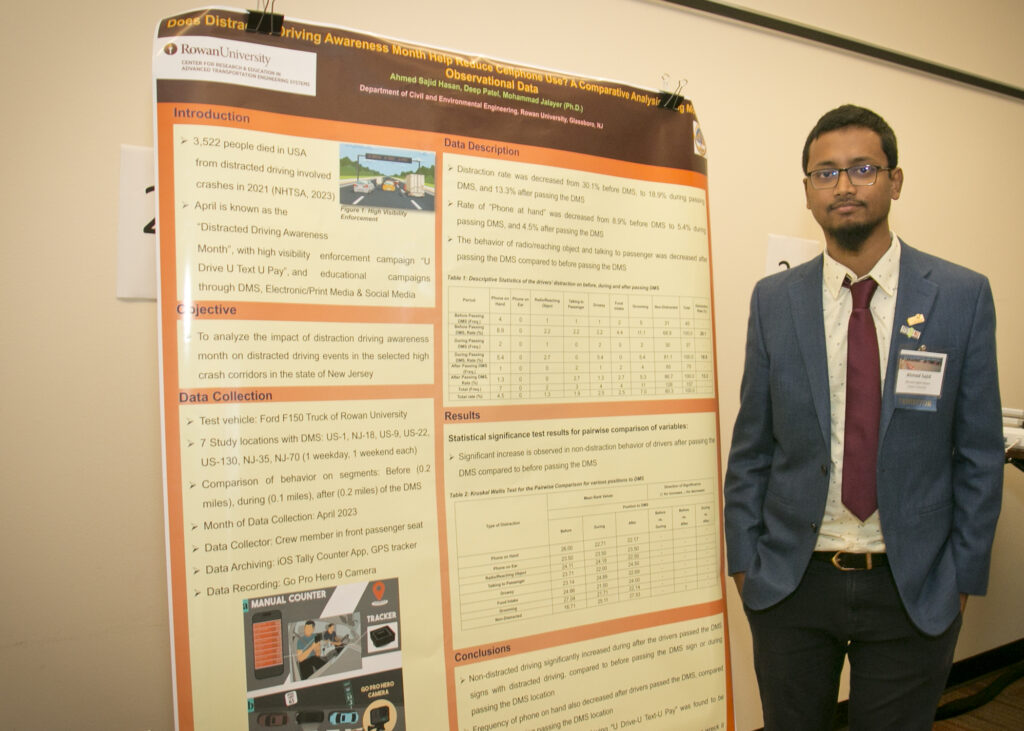

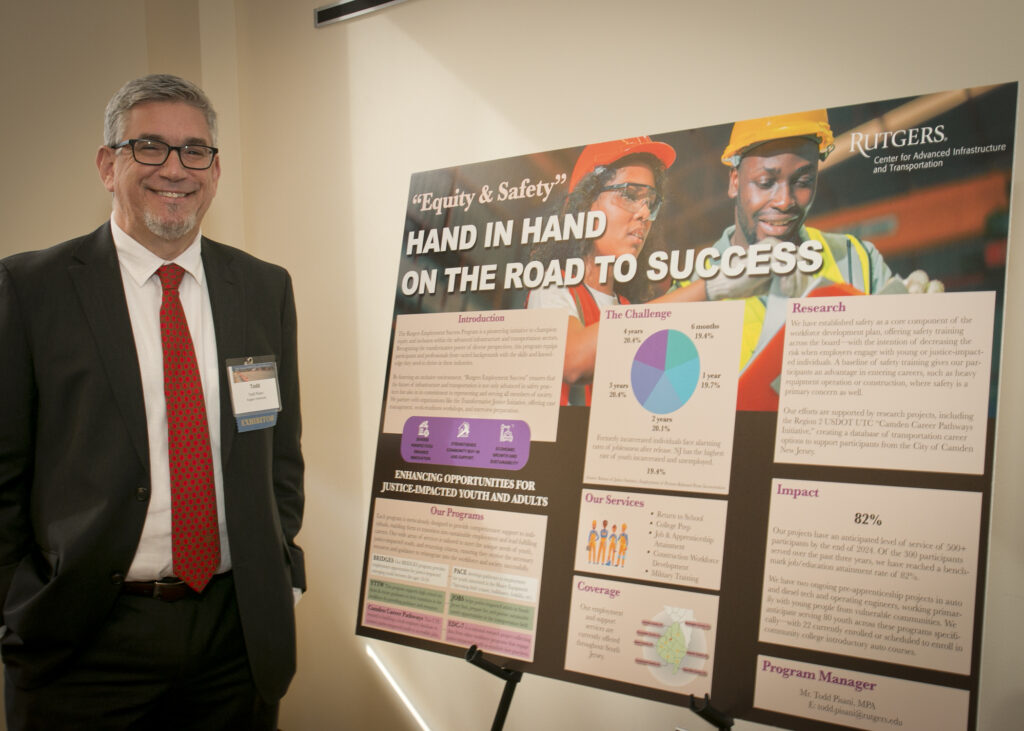

In the afternoon, concurrent break-out sessions were held and research presentations were given on the topics of Equity & Mobility, Infrastructure, and Safety in transportation. Students and researchers at New Jersey’s colleges and universities also presented their research objectives, methods and findings in a concurrent poster session offering those in attendance an opportunity to learn more about ongoing and recently completed research and interact with the researchers.

INFRASTRUCTURE BREAKOUT

EQUITY & MOBILITY BREAKOUT

SAFETY IN TRANSPORTATION BREAKOUT

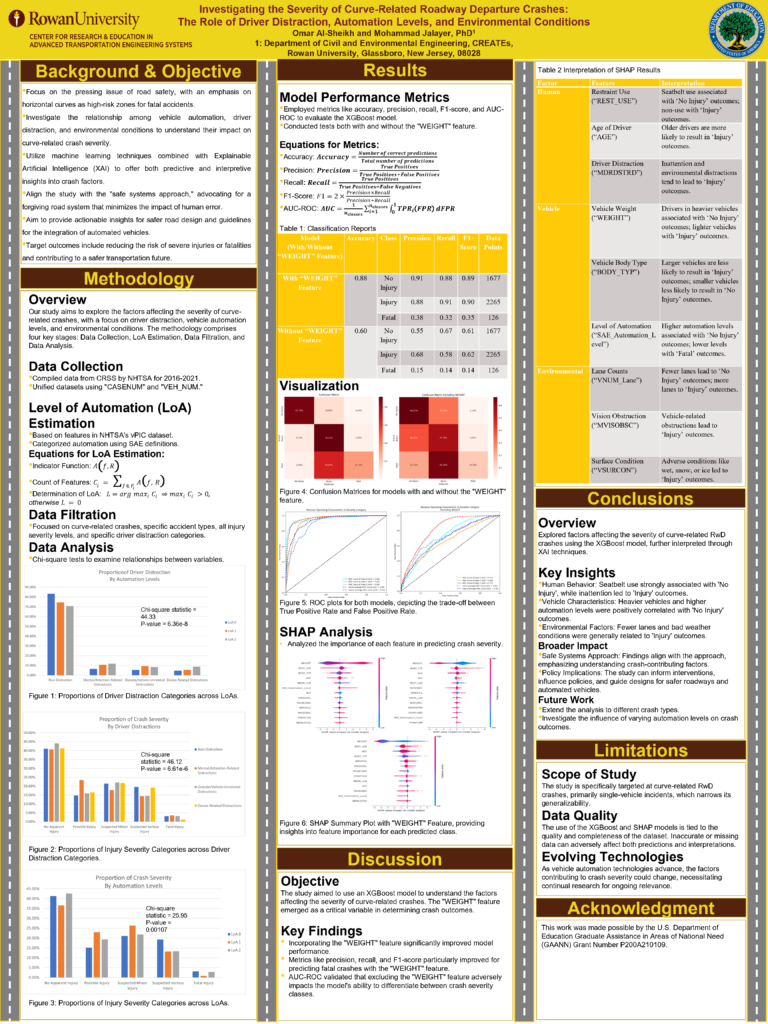

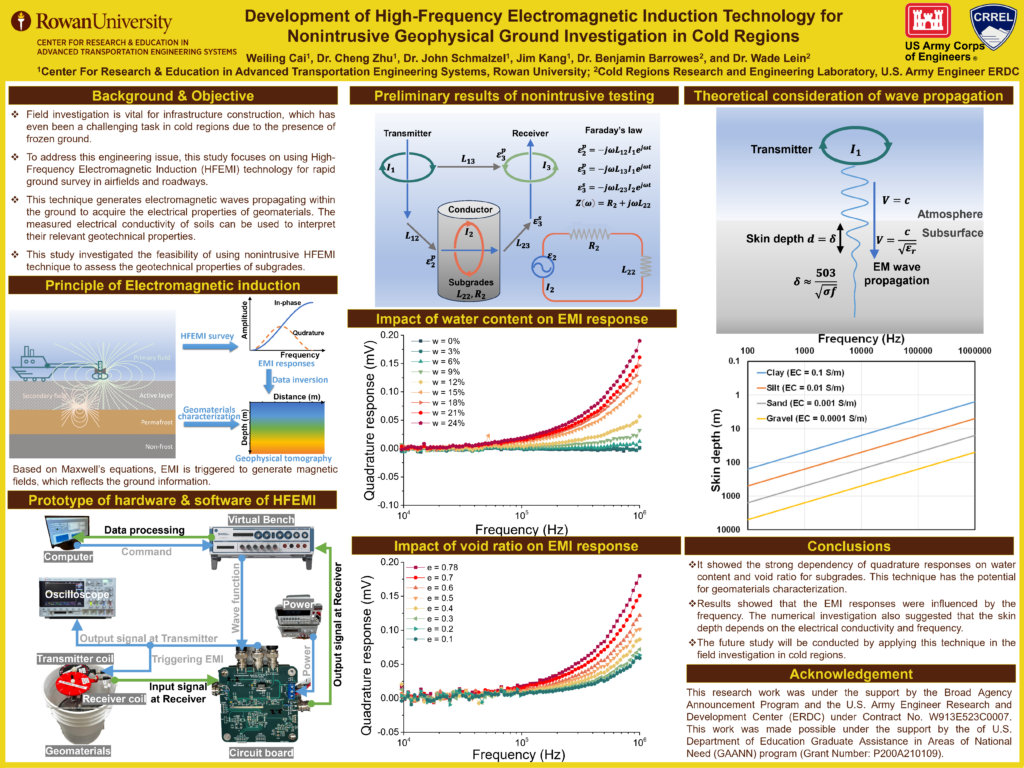

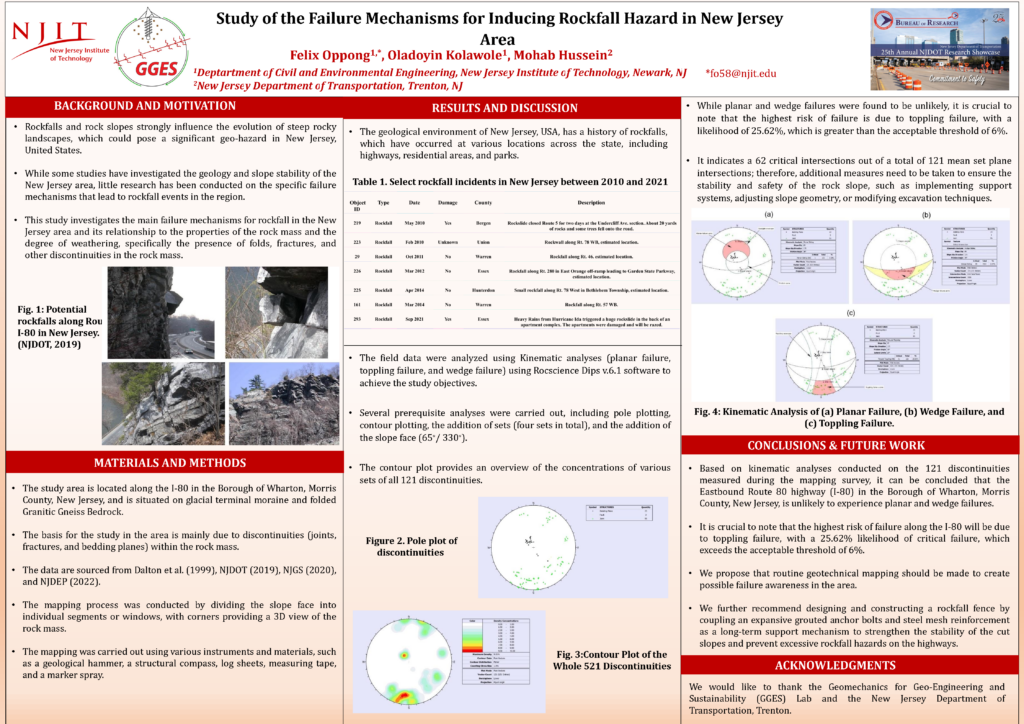

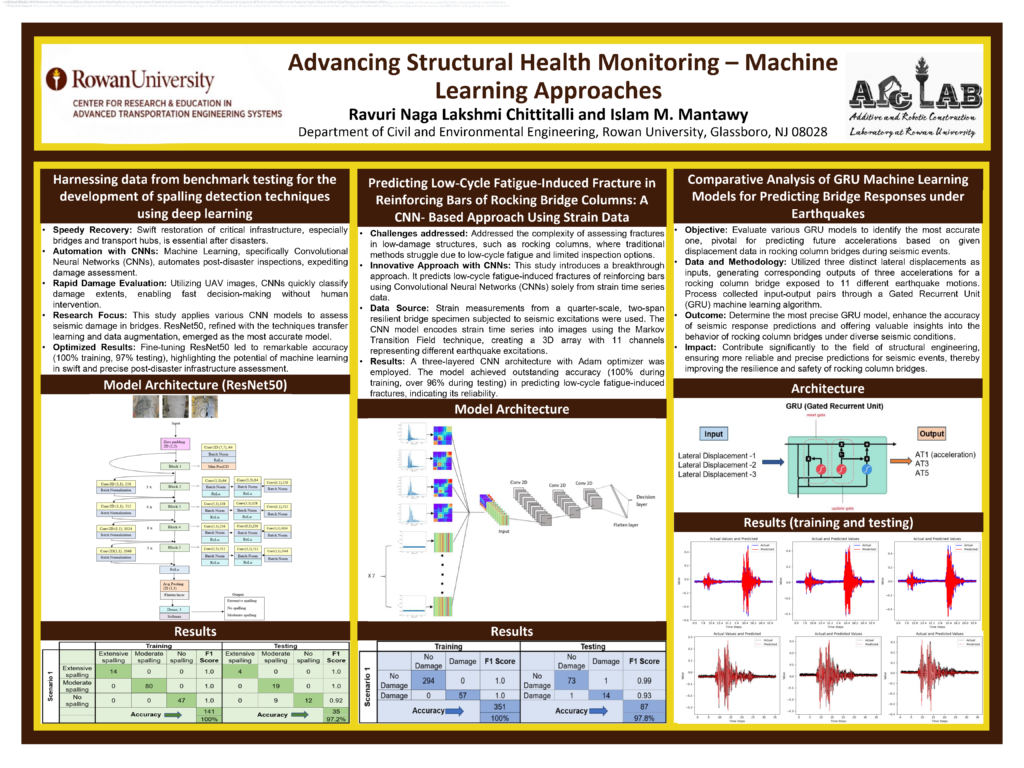

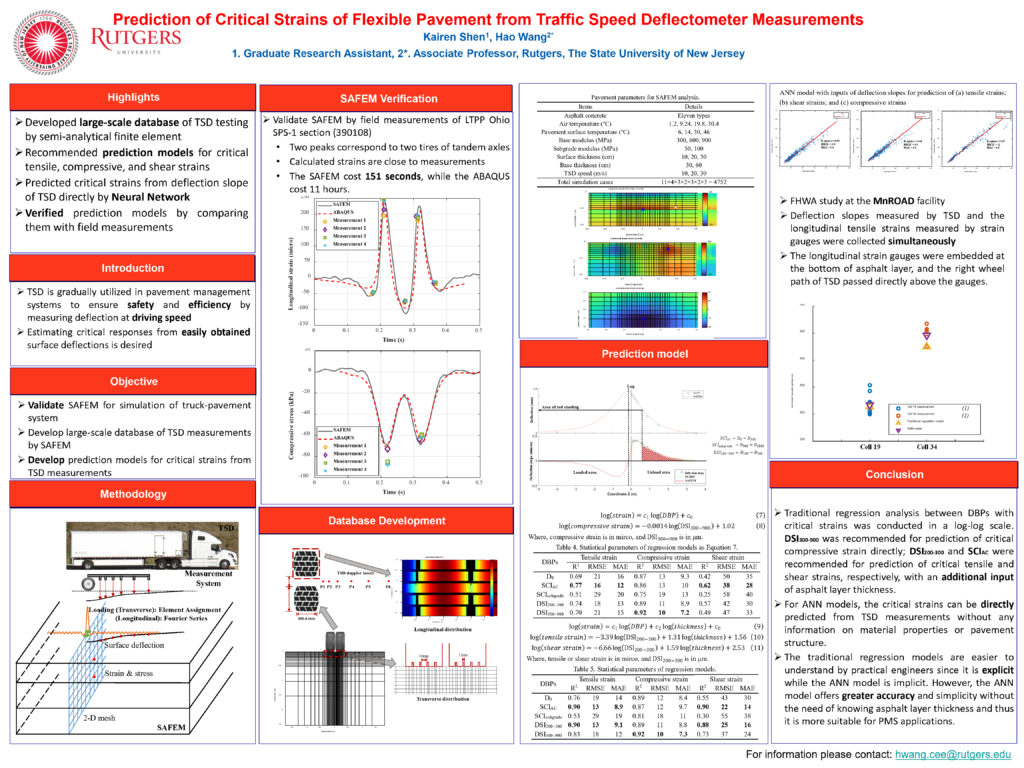

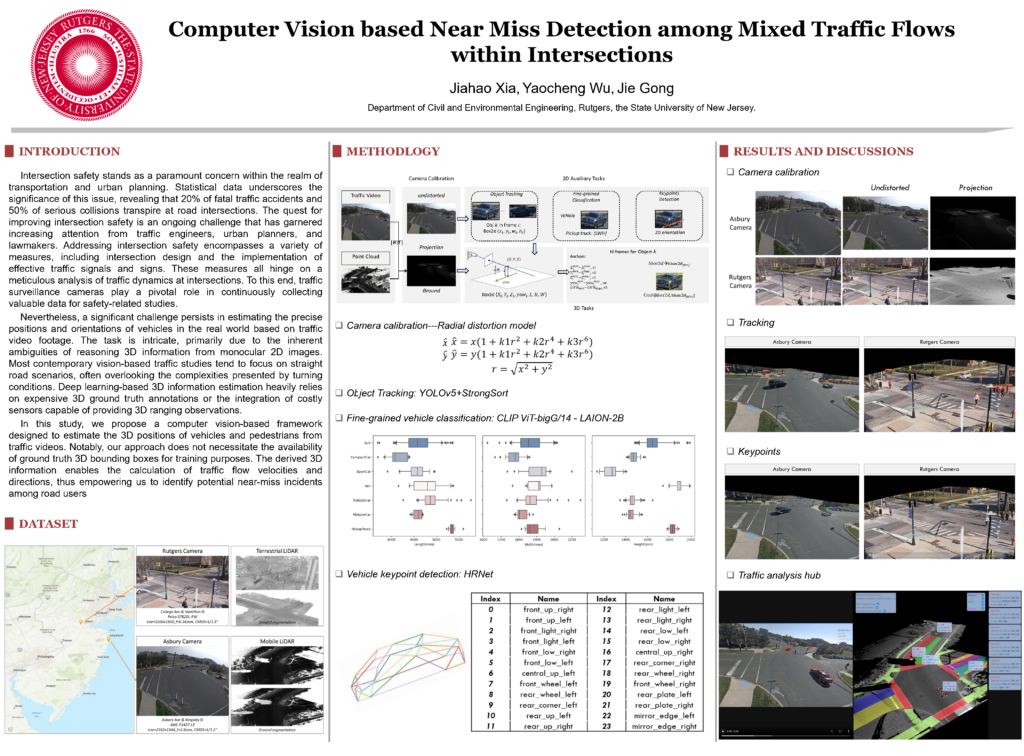

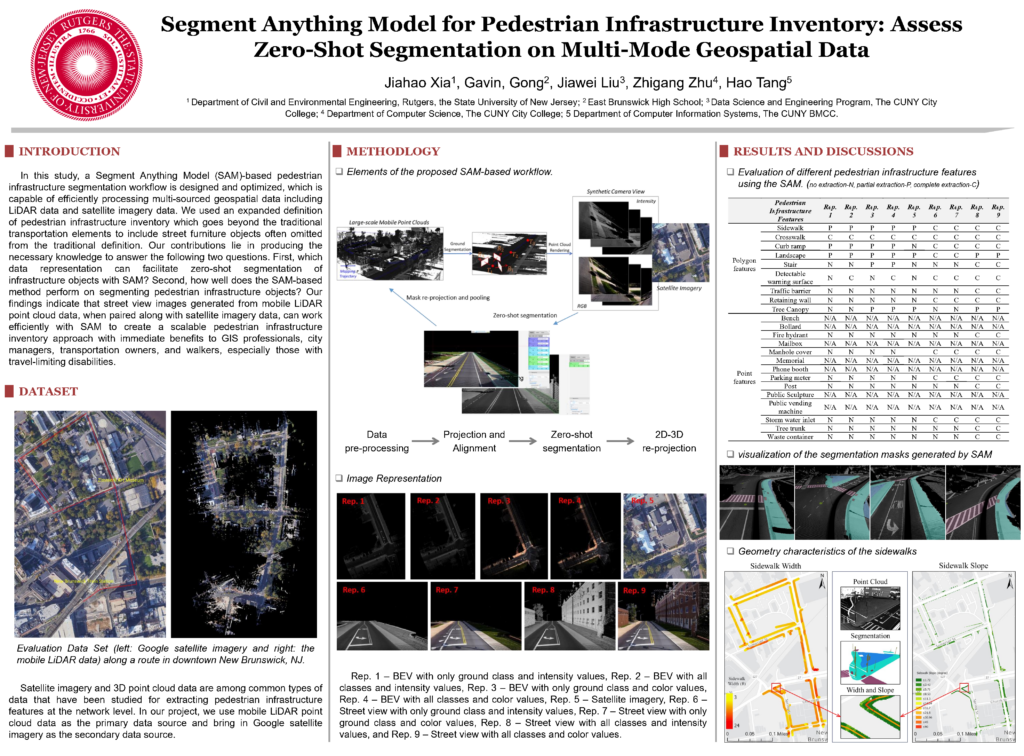

2023 POSTER PRESENTATIONS

The 25th Annual Research Showcase was organized and sponsored by the NJDOT Bureau of Research in partnership with the New Jersey Local Technical Assistance Program (NJ LTAP) at the Rutgers Center for Advanced Infrastructure and Transportation (CAIT) and co-sponsored by the Federal Highway Administration.