Strategic Workforce Development (SWD) is a model innovation in the latest round of the FHWA Every Day Counts (EDC-6). The NJ STIC expressed the objective to “reinvigorate succession planning programs to address workforce development in managerial skills” during this round.

At the 2nd Quarter 2021 STIC meeting, a presentation, Reinvigorating Succession Planning and Special Recruitment Programs, briefed attendees on key features and lessons from a past succession planning initiative undertaken at NJDOT. Subsequently in September 2021, the innovation implementation team participated in a “Let’s Go: Accelerating Innovation through Teamwork” training workshop led by the FHWA to focus on key strategic actions to reinstate and retool succession planning within the agency.

To further inform this effort, the below literature scan highlights examples of succession planning initiatives being undertaken by other leading State DOTs.

Introduction to Succession Planning

NJDOT, as with other state DOTs, can anticipate impending retirements and a continuing loss of knowledge and experience with the retirement of baby boomers in the coming years. NJDOT recognized and addressed the potential loss of qualified leadership with its innovative succession planning program in operation from 2001 to 2010. The GAO (2005) describes succession planning as an ongoing, strategic process for identifying and developing a diverse pool of talent for an organization’s potential future leaders. Succession planning programs are often one element in a larger workforce planning program. Several other techniques of knowledge transfer, including cross-training, job talks, Communities of Practice, and a Lessons Learned database, can be employed within and between units to address potential knowledge gaps.

With a succession planning process, the agency works to anticipate vacancies in key leadership positions, identifies the skills required to fill those positions, and establishes a system of mentoring and professional development to prepare individuals for leadership roles. Increasingly, succession planning programs are also addressing gaps in mission-critical positions at other levels in the organization in response to retirements, promotions and turn-over. Succession planning programs can help DOTs proactively address continuing challenges with employee retention, filling skills gaps within the organization at all levels, finding qualified workers in new technologies and increasing diversity in leadership positions.

State DOTs increasingly recognize the need for leadership to establish a vision and goals for diversity and its close relationship to succession planning. According to Cronin, “In order to ensure diversity is upheld within the highest levels of the organization, it is important that agencies are intentional about their plans for including minorities in their succession planning and that top management fully supports those plans” (Cronin et. al, 2011 p. 104).

Workplace culture plays a large role in employee retention. Improving this culture by providing mentoring, rotational job training, professional development, and succession planning can aid in the retention of transportation employees (Cronin et. al, 2011). Providing career pathways at all levels can help a state DOT compete with the private sector, which tends to offer higher pay, and other public agencies that are vying for applicants with the same skills as are needed at DOTs.

At the most basic level, the availability of career paths “improves job satisfaction, employee motivation, and employee commitment” (Cronin, 2011, p.48). The availability of promotional opportunities for workers and access to continuing pathways for promotion is integral to an agency’s employee retention strategy. Lower-level employees look to see people of similar background in management positions, and advancement opportunities must be visible in order to increase retention. Training programs and individual training plans can create a more flexible employee population and encourage younger employees to stay with the organization. Other retention strategies improve workplace culture by supporting and valuing individual employees, cultural understanding and respect.

State DOTs increasingly face the need to recruit and retain a technically diverse workforce capable of working on emerging technologies to manage infrastructure more effectively and share information quickly. In a recent survey for NCHRP Project 20-07, DOTs identified new and emerging positions that might expose significant gaps in expertise at all levels related to these technologies (Szymkowski and Ivey, 2019).

Succession Planning at NJDOT

NJDOT’s Succession Planning program operated from 2001 to 2010. According to staff, the program was seen as a model for other DOTs around the nation, as it was one of the first formal Succession Planning programs in the U.S. for the industry. The program was initiated as a response to large numbers of retirements and the accompanying loss of critical knowledge. Participants had to be employed at Range 26 or higher to participate. The program included mentoring and training for leadership skills, management, data analysis, team coaching, organizational talent and other competencies required of leaders. With their mentors, participants designed individual development plans. One-to-one coaching and Lunch & Learn sessions provided opportunities to exchange information. Funding for the program covered the program manager’s salary and a staff of three (a secretary, a professional and a paraprofessional.)

The selection process was geared toward managing diversity within the group, with regard to race, gender, location, occupation and employment level. Under the first manager, the application process was open. Anyone interested could apply and applications were reviewed by a Steering Committee, comprised of three directors, two assistant commissioners, one deputy commissioner, and the program manager. In the first year, a total of 53 applicants, or one-half of all applicants, were accepted. In the ensuing years, with five more cohorts instated, the application process became increasingly rigorous. Employees could not self-nominate, but needed two nominations: one from a manager or above in their own division and one from a manager or above outside their division. Applicants had to complete an extensive questionnaire and write an essay. An interview was required with the third cohort, and with the fourth, three nominations were required (one from the director level) followed by a second interview.

Succession planning programs in private industry typically keep their program population to no more than 2 percent of the total employee population. Generally, NJDOT participation was limited to around 60 employees at any one time to avoid having too many trainees prepared for too few positions. Participants were not promised a promotion and it was clear that promotions were constrained by the State’s Civil Service system. Generally, after the first year, between 15 and 30 percent of applicants were accepted to the program. People who were not chosen were encouraged to reapply and some did.

The principal program objective was to prepare people to attain the director level. Several program participants moved into leadership positions, according to staff, but no formal records on the program’s results were kept. Women and minorities were promoted through the program. People could stay in the program for several years. Staff estimated that 130 people went through the program and 7-10 people reached the assistant commissioner level. Transitions in and out of the cohorts occurred when people reached the director level, voluntarily left the program, were asked to leave (if they were not doing the work), retired, or gave their spot to someone else. There was an Associate designation for those who left in good standing but had not reached a director position.

The mentoring piece of the succession planning program was generally acknowledged to be valuable. No formal mentoring program has been instituted since the program’s end. Several former employees served as mentors for participants in the succession planning program. They noted that participation in the program did not necessarily lead to increased opportunities for advancement but provided professional development, self-assessment, and skills improvement that made them better supervisors and managers. Individuals reported that, as mentors, they learned more about the organization. In April 2016, NJDOT’s Women in Transportation group launched a Department-wide mentoring program to encourage the sharing of knowledge and expertise among employees to build “a stronger, more adaptive organization.”

Benefits of Succession Planning

A succession planning program enables a transportation agency to be continuously prepared for the future, and to fulfill its mission to provide mobility and safety continuously to the traveling public. State DOTs and state governments are addressing the issue of potential gaps in key positions with a sense of urgency. Employers are experiencing a wave of retirements and employee transitions fueled by aging baby boomers and disruptions attributable to Covid-19, technological change, and shifting labor market conditions.

Washington State’s DOT (WsDOT) has projected retirement vacancies based on employee age, retirement plans, and years of service. The agency seeks to provide a leadership development program that advances in-house staff and that is attractive to those individuals considering employment at WsDOT. In its Leadership Development Succession Planning Report, the agency notes that “leadership programs not only ease the chain of succession, a good program also makes employees more connected and engaged to the organization. This opens up opportunities for knowledge transfer across the agency …. Additionally, this leadership program supports primary aspects of building a great agency culture, highlighting opportunities for growth and development, which is a compelling recruitment tool for sourcing new talent outside of the agency” (Millar & Pelton, 2018).

Succession planning programs and related knowledge management strategies improve employee morale by providing opportunities to increase knowledge and build expertise, and create a path for advancement. Effective training strategies signal to current and potential employees that the organization is investing in its workforce and is seeking ways to prepare employees to adapt to changing job requirements, acquire new skills, and to promote excellence in the workplace. In some cases, training may also signal the agency’s intentions to prepare its employees for greater managerial responsibilities. Such training may increase retention by improving the readiness of an employee for a new position.

Existing Practices

Although specific content and curricula of succession planning programs in other states is generally unavailable through desktop methods, many DOTs and state government agencies provide guidance for establishing programs.

State DOTs and State Governments

Several state DOTs, including those in Georgia, Oregon, Virginia and Wisconsin, provide a framework for the organization of succession planning programs. In addition, state governments are facing the issues of retention and the retirement of baby boomers and have provided guidelines for establishing succession planning programs for adoption by all of their state agencies, including DOTs.

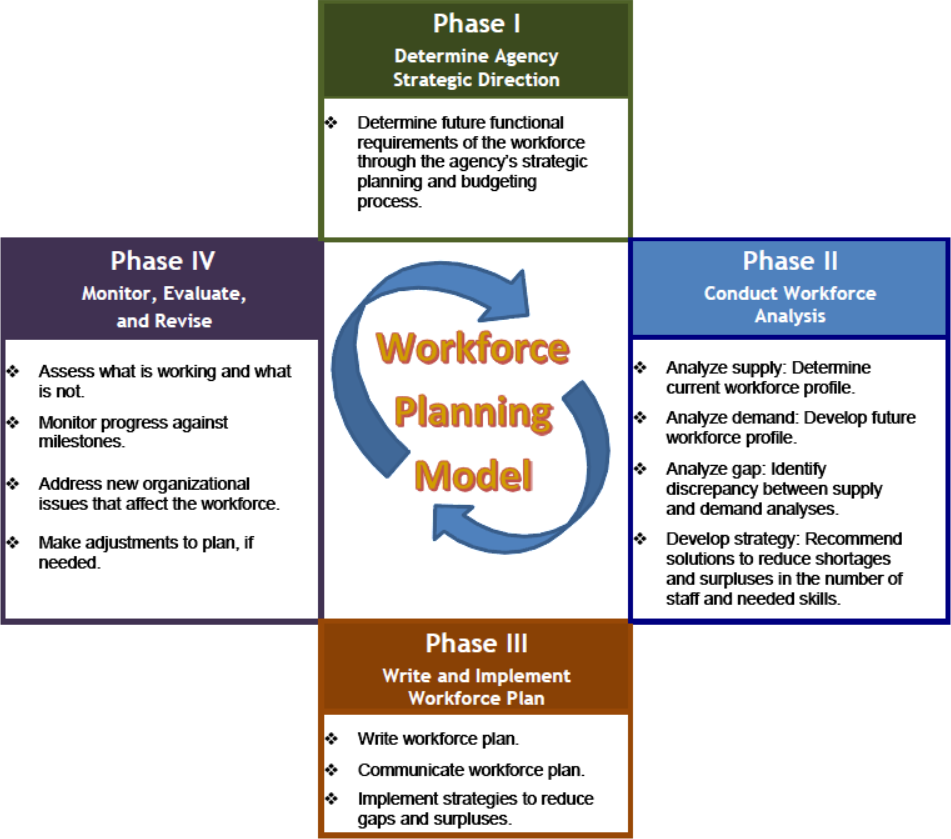

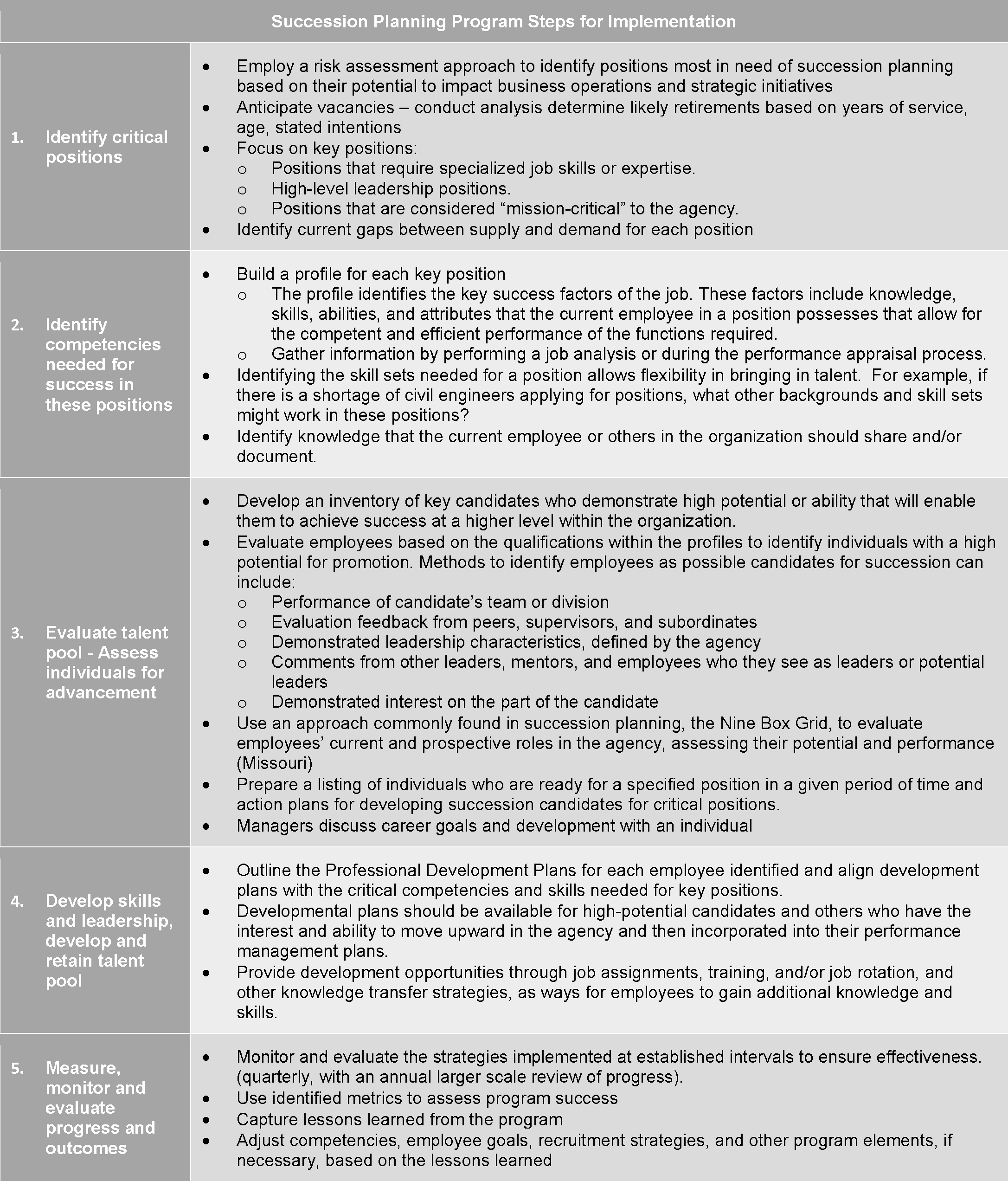

In general, these guides present similar steps for successful implementation of succession planning programs. Not all guides include all of the steps (See Table 1).

Table 1. Succession Planning Program Steps for Implementation

Links to examples of worksheets and forms, from the state governments of Michigan, Missouri, Ohio and Oregon, designed to assist with implementing and recording these steps can be found in the resources section below.

Leadership Training for All

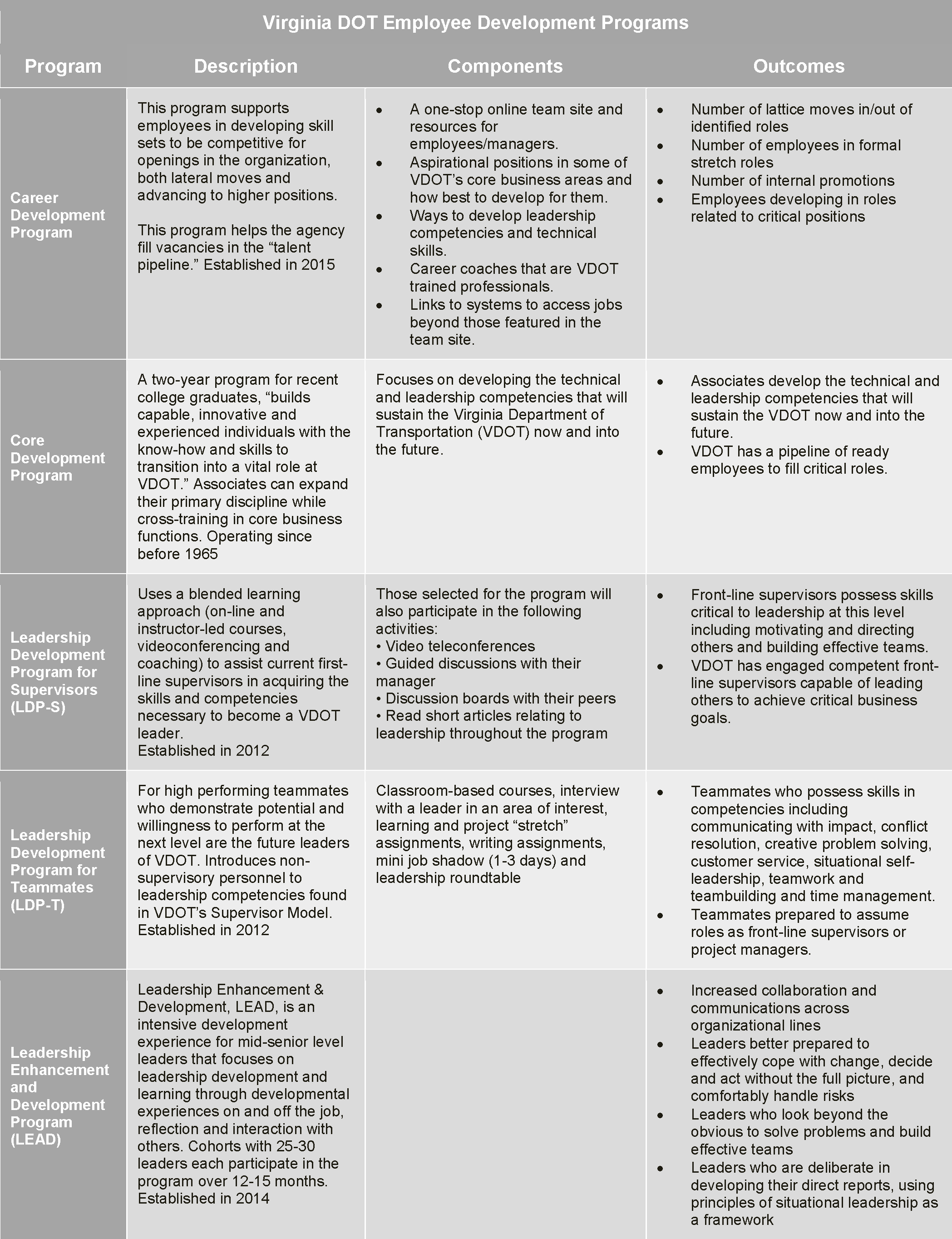

Nevada, Utah, Virginia and Washington DOTs have leadership training programs for employees at almost all levels of their organization. Leadership training programs enable employees to improve their leadership skills and knowledge of the organization and may prepare participants to be more competitive for positions in other units, even if they are not focused on upper management positions. Some of these programs are self-initiated and self-paced.

Washington DOT developed a five-track program open to employees at all levels of the organization. The program content, aligned with a statewide leadership development program, is available through the agency’s learning management system. Utah DOT (UDOT) has a four-tiered Leadership Development Program that all employees can participate in, until the last step in the program, the Utah Leadership Institute, which is only open to individuals by invitation from agency senior leadership. Nevada DOT developed a Leadership Academy based on The Leadership Challenge®. The program is open to all DOT employees. Information on this program is located on the NDOT Careers page, as a recruitment strategy.

Virginia DOT has a comprehensive set of programs to assist all interested employees gain leadership skills and advance internally. Each of the programs have metrics such as the number of employees who were able to move laterally or up in the organization, skill acquisition, or acquisition of leadership competencies, among others (See Table 2).

Table 2. Virginia Department of Transportation Employee Development Programs

Source: University of Memphis & VDOT

Source: University of Memphis & VDOT

Emerging Practices

Knowledge Management

Succession planning can be a standalone program or part of a larger workforce planning program. Several knowledge management strategies can be employed to transfer knowledge between mentor and mentee in the succession planning process. These strategies also frequently factor into workforce planning. Any employee exiting the organization may have decades of experience, technical expertise, and institutional knowledge, that should be captured. The agency needs to identify critical knowledge that should be captured, and identify effective knowledge sharing tools for the types of knowledge to be transferred, and the audience (State of Texas, 2013).

Some of the following strategies, tools and techniques can be built into the individual development plan for employees selected for the succession planning program. All of these strategies, tools and techniques could be considered for agency-wide implementation.

Table 3. Knowledge Management Strategies, Tools and Techniques

|

Strategies, Tools and Techniques |

Description |

| Annotated Template/ Guidance Document | Templates, outlines, or other content/format guidelines to provide guidance on items for inclusion and how to go about writing and documentation. |

| Communities of Practice | A group of people who deepen their knowledge and expertise by interacting with each other over time and who share that collaborative knowledge with others in the organization, but not a formally constituted work team. |

| Critical Incident Review/ Lessons Learned | Capture lessons of experienced employees’ approach to problem solving. Creates a database and allows for discussion of what worked, what did not work, and why. Focuses on finding root causes and process issues |

| Cross-generational Mentoring | An agreement describes formal and informal meetings to mentor employees new to the organization. Can include “reverse-mentoring” in technology-related areas to include experienced employees willing to be mentored by younger employees. |

| Cross-training and mobility assignments | Training of employees to learn about other positions in the organization, and to perform the job functions while maintaining their own position. |

| Desk-Side Reviews | A successor sits down with the upcoming retiree at the retiree’s desk and listens as they show notes, templates, shortcuts, or memory aids for performing the job. |

| Expert Interviews | Skilled interviewer asks questions of employee to make tacit knowledge explicit. |

| Job Shadowing | Veteran employee shares knowledge with a less experienced employee and provides hands-on practice in dealing with everyday problems and the most difficult situations |

| Knowledge Maps | Used to discover the location, form, ownership, value and use of knowledge and people’s expertise to make better use of knowledge and identify barriers to knowledge flow. Can help to identify areas in need of succession planning. |

| Last Lecture/Story Telling/Oral History | Retiring employee or employee with expertise is encouraged to give a presentation in a staff meeting and/or lunchtime talk. Event can be face-to-face or via a video. Description of what really happened to give context, engage feelings and minds, help listeners see relevancy to their own situation |

| Mentoring Programs | Training for specific situations or developmental needs, effective for transferring organizational cultural information, relationships outside units, develop higher level of proficiency |

| Peer Exchange | Peers from state DOTs, or regional and local governments, meet to exchange ideas and best practices on a specific topic to benefit research, development, and technology transfer programs. |

| Procedure Manual | Manual that describes the specific processes and procedures required to accomplish the work of a unit or of a particular position. |

| Process Documentation | Flow diagrams that illustrate a process and identifies roles and responsibilities of various parties, including process, participants and products at each step in the process. |

| Research | Research advances innovation and contributes to broad implementation of specific processes and procedures. |

| Tech Talk Events | SMEs present information on specific innovative initiatives or research findings at lunchtime talks or half-day events |

| Training | SME conducts training session on specific topic |

| Videos | Illustrates how a job or task is done or innovation is achieved. Documents model or innovative practices. |

| Webinar | SMEs conduct online training that can be accessed live or reposed for on-demand use. |

| Workshop | Half-day or full-day event including practical application of knowledge transferred. |

Challenges

When implementing succession planning, DOTs may face barriers from other institutions such as civil service systems and unions.

Civil Service System

The Civil Service system in New Jersey State Government greatly affects NJDOT’s approach to recruitment, retention, and advancement of its workers. The NJ Civil Service Commission (NJCSC), part of the State Treasury department, oversees the implementation of these regulations. Recruitment and hiring for most NJDOT job titles is subject to the NJCSC’s competitive hiring and recruitment system. All applicants for “Open Competitive positions” must score highly on a Civil Service test and/or meet other requirements. NJCSC operates under the “Rule of Three” under which NJDOT must select from the first three highest ranking candidates on a given list.

NJCSC seeks to ensure adherence to the Disabled Veterans and Veterans “Absolute Preference” requirements in hiring and promotion. The “Rule of Three” and “Absolute Preference” are applied differently in Open Competitive and Promotional examination situations. While Veterans and Disabled Veterans have an absolute preference when creating the rank of the eligible lists over all other candidates in order of their scores, promotional exam eligible lists differ in that all candidates, including veterans, are ranked by their score with no distinction among disabled veterans and veterans in promotional exams. However, when a veteran is ranked number one on a promotional certification, a nonveteran cannot be appointed.

To ensure access to skilled workers under hiring freeze conditions and periods of skilled worker shortages, the State has created two processes that allow State agencies to bypass some Civil Service rules during the recruitment and hiring process. The first of these are positions designated as “non-competitive”, which include civil engineering trainees (CETs) and other titles approved by the Civil Service Commission. For these positions, most Civil Service requirements are waived for the initial hiring process, and workers in these positions do not need to test at all for their entry-level promotion, but are required to follow Civil Service rules for any subsequent promotions. The second type of position is referred to as a “provisional trainee.” Faced with the possibility that approval for open positions might be rescinded, NJDOT may hire in advance of the test. A provisional trainee must test after hire to hold the position, but exams are administered infrequently.

Most positions available at NJDOT are subject to Civil Service Rules either at the point of hiring and/or at the point of promotion. The only positions that are not subject to Civil Service rules in any form are considered “unclassified” positions, also known as political appointee positions. These include many leadership positions, including the Commissioner and Assistant Commissioners. However, there are also a select number of additional “unclassified” positions, including “special assistants” who oversee the agency’s increasing number of outside contracts. The number of unclassified positions is determined by statute.

Recent structural shifts, such as the stepped testing and advancement available through the Vision 2020 program, and the expanded promotion of Assistant Engineers to Senior Engineers, offer examples of NJDOT initiatives that have the support of the Civil Service Commission.

Union Environment

Succession planning programs may be perceived as bypassing traditional hiring processes and privileging a potential successor for a particular position, a process that unions would oppose for positions covered by collective bargaining agreements. Including union representatives when developing succession planning programs can help address issues early in the program development.

Recommendations

Most of the guidance developed by other state governments includes a caveat that participation in a succession planning process is not a guarantee of promotion, and does not replace a competitive hiring process. The former NJDOT program included similar language. Employees in succession planning programs may need to be assured that there are no negative repercussions if they leave the program, and must fully understand the expectations and limitations of the program.

By providing various training opportunities that are open to all, no matter what level, the agency avoids the perception that it supports an “elitist” training program.

Participation in programs should not depend solely on the need for a supervisor’s recommendation. Individuals may have conflicts with supervisors and may not be able to request that recommendation.

New Technologies

New technologies require skills sets that may not be represented in the agency. Agencies need to predict technological advances, conduct a gap analysis at all levels to determine if current employees have the skills required for these technologies, there is a need to train current employees for this work, or if there is a need to hire for these positions. State DOTs increasingly face the need to recruit and retain a technically diverse workforce capable of working on emerging technologies to manage infrastructure more effectively and share information quickly. In a recent survey for NCHRP Project 20-07, DOTs identified new and emerging positions in Transportation Systems Management and Operations (Szymkowski and Ivey, 2019). (See Text Box)

Moving Forward

Many of the state DOTs and state governments express the need for immediate action when considering impending gaps in agency leadership. At this critical time, NJDOT is considering the renewal of the succession planning program, to include two levels, for leadership positions and management positions. Providing mentoring and training to program participants will prepare them to assume leadership positions to guarantee consistent service to the traveling public.

Resources

The following documents provide examples of templates and forms for implementing the steps of a succession planning program.

State of Michigan. Succession Planning Tool Kit. https://pdf4pro.com/view/succession-planning-tool-kit-michigan-gov-54f9d.html

State of Missouri. Succession Planning Playbook. https://leadershipacademy.mo.gov/documents/Class3/20200203%20MLA%20-%20Class%203%20-%20Capstone%20Team%20B%20-%20Playbook.pdf

State of Oregon. Employee resources and state workforce: Succession Planning. https://www.oregon.gov/das/HR/Pages/success-plan.aspx

Bibliography

Cronin, B., Anderson, L., Heinen, B., Cronin, C.B., Fien-Helfman, D., & Venner, M. (2011). Strategies to Attract and Retain a Capable Transportation Workforce. NCHRP Report 685. Washington, D.C.: National Cooperative Highway Research Program, Transportation Research Board of the National Academies. https://www.trb.org/Publications/Blurbs/164747.aspx

Meadati, P., Toson, S., & Jambro, J. 2014. Georgia Department of Transportation (GDOT) Leadership Academy.http://www.dot.ga.gov/BuildSmart/research/Documents/GDOT%20Leadership%20Academy%20Final%20Report.pdf

Government Accountability Office (GAO). (2005). Diversity Management: Expert-Identified Leading Practices and Agency Examples. Washington DC: Government Accountability Office. https://www.gao.gov/products/gao-05-90

Millar, R. and Pelton, J. 2018. Report on Agency Succession Planning & Leadership Training. Washington State Department of Transportation. https://wsdot.wa.gov/publications/fulltext/LegReports//17-19/WSDOT_LeadershipDevelopmentSuccessionPlanningReport.pdf

National Academies of Sciences. 2019. Transportation Workforce Planning and Development Strategies. Washington, DC: The National Academies Press. https://doi.org/10.17226/25624.

National Academies of Sciences. 2015. A Guide to Agency-Wide Knowledge Management for State Departments of Transportation. Washington, DC: The National Academies Press. https://doi.org/10.17226/22098

Nevada Department of Transportation. 2021. NDOT’s Leadership Academy for Employees. https://www.dot.nv.gov/doing-business/careers

State of Michigan. (n.d.) Succession Planning Tool Kit. https://pdf4pro.com/view/succession-planning-tool-kit-michigan-gov-54f9d.html

State of Missouri. Succession Planning Playbook. n.d. https://leadershipacademy.mo.gov/documents/Class3/20200203%20MLA%20-%20Class%203%20-%20Capstone%20Team%20B%20-%20Playbook.pdf

State of Ohio. 2011. Ohio’s Talent for Tomorrow and Beyond, Succession Planning Manager’s Toolkit. https://www.das.ohio.gov/Portals/0/DASDivisions/HumanResources/LPD/pdf/Succession%20Planning%20Product%20Documentation.pdf

State of Oregon. Employee resources and state workforce: Succession Planning. https://www.oregon.gov/das/HR/Pages/success-plan.aspx

State of Texas Auditor’s Office. 2017. Workforce Planning Guide. https://sao.texas.gov/Reports/Main/17-708.pdf

Tennessee State Government. 2017. Agency Guide to Workforce/Succession Planning. https://www.tn.gov/content/dam/tn/hr/documents/Agency_Workforce_Succession_Planning_Guide.pdf

Szymkowski T. and Ivey, S. 2019. TR News: Job Openings for Transportation System Management and Operations. Washington, D.C., The National Academies. https://www.trb.org/Publications/Blurbs/180431.aspx

University of Memphis and VDOT. n.d. Virginia Transportation Training Programs. https://www.memphis.edu/setwc/docs/va_compendium.pdf

Utah Department of Transportation. 2021. Leadership Development. https://www.udot.utah.gov/connect/employee-resources/employee-training/udotu/leadership-development/