A recently completed NJDOT research study, Innovative Pothole Repair Materials and Techniques, tested several new techniques and materials that could improve the cost-effectiveness of pothole repairs in New Jersey. Phase I of the research project, led by Professors Hao Wang and Husam Najm of Rutgers University, evaluated new methods for both asphalt and concrete structures. Pothole repair is one of the primary maintenance activities for highway agencies, generating significant costs and resource commitments. Cost-effective pothole repair methods can reduce or eliminate the possibility of re-patching and save future repair costs.

Asphalt Pothole Repair

Asphalt pavement is continuously subjected to vehicular and environmental loading throughout its lifecycle, leading to the inevitable occurrence of distresses such as cracking, rutting, raveling, potholes and so on. Among these distresses, potholes are critical as they can disrupt traffic, impose risks to safety, and cause costly vehicular damage for vehicle operators.

Pothole repair is a primary maintenance activity for highway agencies. Typically, cold mix asphalt is used for emergency repair and hot-mix asphalt (HMA) for traditional repairs. Usual pothole repair methods include throw and go (roll), edge seal, semi-permanent, spray injection, and full depth repair. Among them, throw and go (roll) method using HMA has been adopted by most transportation agencies for surface patching. However, this common practice largely relies on the usage of HMA. Although the quality of the asphalt patch can be ensured, it presents environmental concerns due to the energy consumption and environmental footprint involved in producing new HMA. To mitigate the impact on the environment, reduce cost and conserve energy, recycled asphalt pavement (RAP) has been widely used as a highly desirable material. The addition of recycled asphalt pavement (RAP) in asphalt mixtures can bring numerous economic and environmental advantages.

This study sought to investigate an innovative approach to pothole repair using HMA with RAP and preheating. The study investigated two aspects: First, the performance of HMA with different RAP contents were evaluated through laboratory tests to select the most appropriate content. Second, the in-site strength of pothole repair was evaluated with field cores to quantify the benefits of repair quality due to recycled material and preheating.

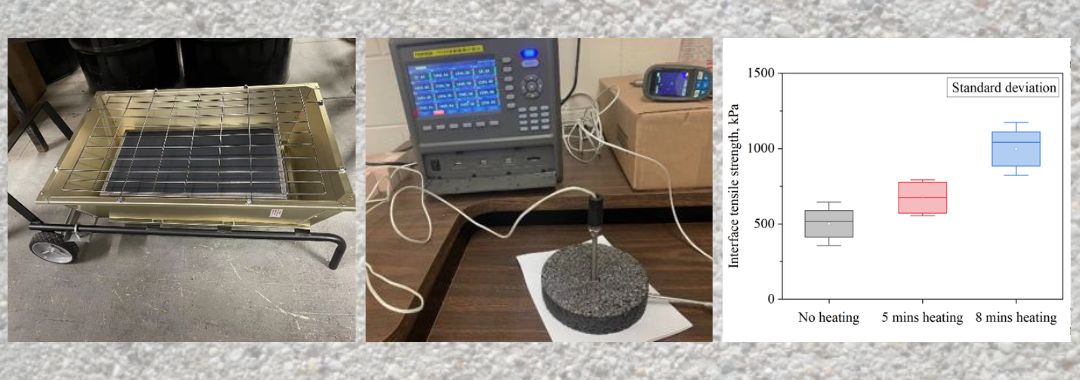

Both microwave heating and infrared heating were tested, with varying results. Microwave heating was able to warm both the surface and internal materials of the pavement, however, its efficiency was low and the rate of temperature increase was insufficient. Conversely, the infrared heating method proved adept at rapidly heating the top edges and bottom surface of the pothole to high temperatures and was used successfully in pothole repair.

Further tests were carried out adding RAP to HMA patching materials. The results showed that there was greater abrasion loss, reduced IDT (indirect tensile strength), and interface shear strength of patching material had less resistance to moisture as RAP content increased. Nonetheless, with the application of preheating, the overall performance of HMA containing 30 percent RAP was satisfactory, proving that it is feasible to use RAP material for pothole repair.

Concrete Pothole Repair

Similar to asphalt pavement, concrete structures are prone to deterioration due to vehicles and weathering. Cracks can develop which lead to further deterioration due to chloride infiltration. Thus, a good repair is necessary for maintaining concrete structures. An ideal repair material should be easy to work with under different weather conditions, be fast setting, and possess good durability. Rapid-setting cementitious patch repair materials are popular for repairing small concrete damage and providing a functional repair within few hours.

Based on extensive literature research and several NJDOT practices, three formulations were chosen as the best performing candidates. Workability, strength, and restrained shrinkage cracking of the formulations were investigated. The restraint shrinkage test protocol simulated upper and lower limits of restraint that a repair material undergoes in real applications. The repairs were also cast and placed in external environmental conditions to expose them to natural weathering actions. The cracking behavior was evaluated including cracking spacing and maximum crack width

The investigation led to the identification of three formulations that did not crack for a period of 10 months in field exposure to NJ climate conditions. Typically, rapid set formulations do not shrink after 6 months. The formulations that did crack revealed that an addition of 1 percent of PVA fibers could significantly reduce the maximum crack width. The maximum crack widths observed in all the formulations were an order of magnitude less than the maximum allowable crack width specified by NJDOT (1/32″).

Contemplated Legislation

The research projects were completed at a time when pothole repairs have attracted critical attention from motorists and legislators within the state. In the current legislative session (2024-2025), the New Jersey State Senate voted unanimously to advance a bill that is intended to address concerns about pothole damage to roads and bridges in the Garden State.

The NJ Senate bill, S862, would require the state DOT to include information about pothole repair projects and their cost in the annual report. The additional information would include reporting on the number of repair projects going on around the state and their cost. The bill includes a separate provision that would require a lifecycle cost analysis to be conducted. The information would be required to be made available to the public on the NJDOT’s website. An identical bill, A2596, was introduced in the NJ Assembly during the legislative session.

AASHTO Recognition

The research project is not only primed to inform the serious legislative issues being raised in Trenton but was recently recognized by the American Association of State Highway Officials (AASHTO) for its contribution to innovation. Every year, the High Value Research Task Force of AASHTO Research Advisory Committee (RAC) holds a national competition to find “high value” research projects throughout the country. In 2024, the Innovative Pothole Repair Materials and Techniques research project was recognized in the Maintenance, Management, and Prevention supplemental category, as described here.

Resources

Wang, Hao, and Xiao Chen. (2024). “Innovative Pothole Repair Materials and Techniques Volume I: Asphalt Pavement.” Final Report. http://njdottechtransfer.net/wp-content/uploads/2024/02/NJDOT_Pothole-Repair_Final-Report-Volume-I.pdf

Wang, Hao, and Xiao Chen. (2024). Innovative Pothole Repair Materials and Techniques Volume I: Asphalt Pavement. Technical Brief. http://njdottechtransfer.net/wp-content/uploads/2024/02/NJDOT_Pothole-Repair_Technical-Brief-Volume-I.pdf

Najm, Husam, Bala Balaguru, Hao Wang, Hardik Yagnik, and Alissa Persad. (2024). “Innovative Pothole Repair Materials and Techniques Volume II: Concrete Structures.” Final Report. http://njdottechtransfer.net/wp-content/uploads/2024/02/NJDOT_Pothole-Repair_Final-Report-Volume-II.pdf

Najm, Husam, Bala Balaguru, Hao Wang, Hardik Yagnik, and Alissa Persad. (2024). “Innovative Pothole Repair Materials and Techniques Volume II: Concrete Structures.” Technical Brief. http://njdottechtransfer.net/wp-content/uploads/2024/02/NJDOT_Pothole-Repair_Technical-Brief-Volume-II.pdf

Asphalt Pavement Pothole Repair with Recycled Material and Preheating. Presentation at NJDOT Research Showcase by Xiao Chen and Hao Wang. Presentation.